Many companies in Baden-Württemberg possess specialized knowledge in the process chain for manufacturing a combustion engine. However, there is a trend towards electric vehicles. Such a strategic reorientation is very difficult in particular for small and medium-sized enterprises (SME). To help SME cope with this challenge, a “Transformation Hub Electric Mobility” is now being established at KIT. The hub is funded by the state of Baden-Württemberg with EUR 2.6 million.

“The ‘Fit4E’ project of the Transformation Hub Electric Mobility is to help companies identify own strengths and competencies,” says Professor Jürgen Fleischer of KIT’s Institute of Production Science (wbk). “Together, we will then identify the overlap with electromobility technology and the use case for adopting the new process chains.”

The Transformation Hub will first launch the framework project “Fit4E” and two lighthouse projects scheduled for a duration of two years each. Upon establishment of the future “Karlsruhe Research Factory,” the hub will be connected with it. “’Fit4E’ directly addresses machine and plant engineers in Baden-Württemberg,” says project coordinator Janna Hofmann of wbk. These companies mostly are world market leaders in their process step that still is part of the “old” process chain for the combustion engine only. “We will organize training courses at the hub and help the companies find out how they can use their skills and competencies in the production chain of an electromobile drive train as well.”

The “AgiloBat” lighthouse project is to establish a modular plant for manufacturing battery cells on the pilot scale that responds flexibly to changes of numbers of pieces and formats. The smallest modular unit, the “Smart Battery Maker,” is a production robot for process steps like coating and drying or separation and stacking that does not need any big infrastructures, such as large drying rooms. With their expertise in precision engineering, SME are often better prepared for the process than they think. Three working groups of KIT cooperate in this project, the Thin Film Technology Group of the Institute of Thermal Process Engineering, the Energy Storage Systems Group of the Institute for Applied Materials, and the wbk group. A group of Fraunhofer ICT has joined the project.

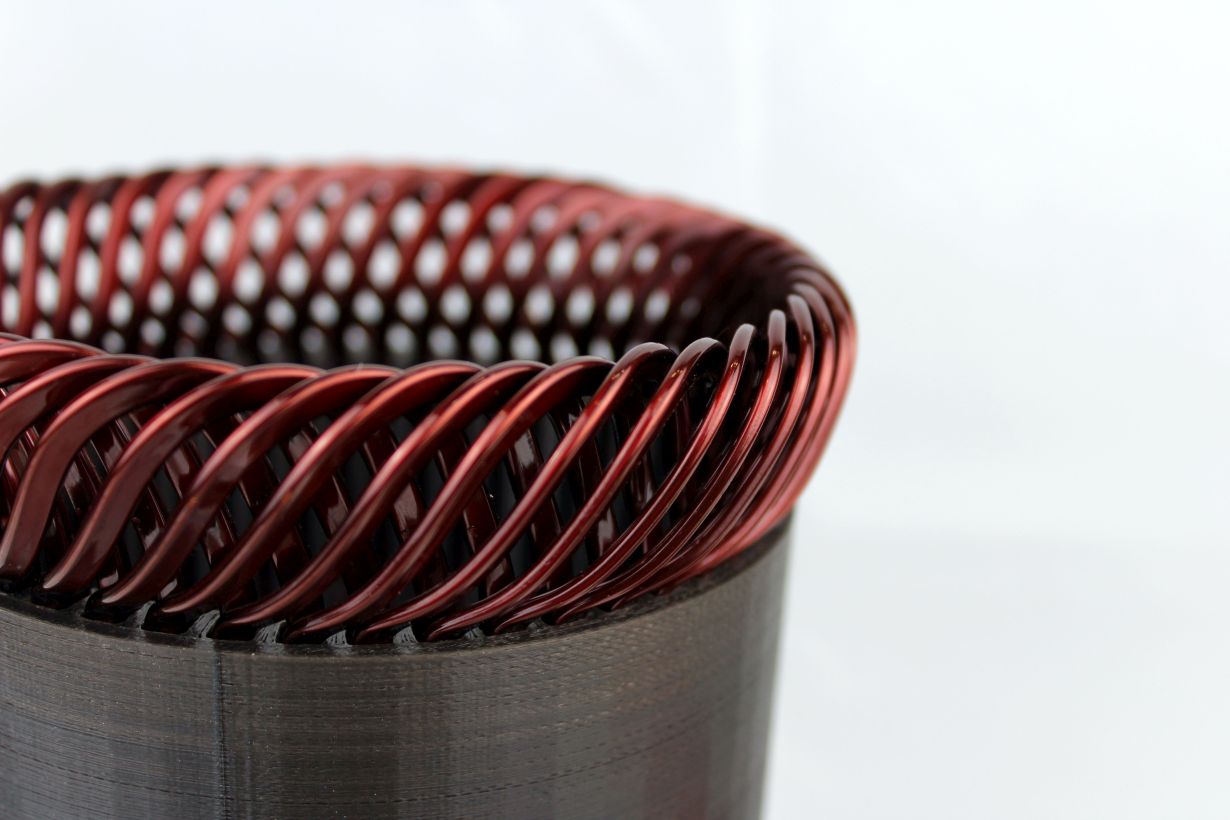

The lighthouse project “Training Factory for Stator Manufacture” works together with the corresponding vocational schools in Karlsruhe and addresses trainees. A training and teaching concept is developed, with the manufacture of hair pins for stators – these are special wire windings for electric motors – being used as an example. It is based on existing process modules of the “AnStaHa” project that focuses on the flexible production of electric motors. At the training factory, trainees are to learn how to manufacture an electric drive, which is not always possible at the company where they work.

More information:

https://www.wbk.kit.edu/wbkintern/Forschung/Projekte/AusbildungsfabrikStatorfertigung/index.php (in German only)

https://www.kit.edu/kit/english/pi_2017_126_flexible-production-of-electric-motors-for-vehicles.php

https://www.kit.edu/kit/english/pi_2019_002_on-the-way-to-research-factory-karlsruhe.php

https://www.forschungsfabrik-ka.de/servlet/is/65033 (in German only)

More about the KIT Mobility Systems Center http://www.kit.edu/research/6720.php

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.