Vasodilating stents, “labs-on-chips” for analysis on smallest areas, 3D cell culturing systems for tissue reconstruction: microtechnology is gaining importance in the medical sector. It also opens up new potentials in the area of implantology. Scientists of Karlsruhe Institute of Technology (KIT), together with experts for dental implants, have now developed a nanostructured surface to accelerate wound healing after implantation and to better protect it against the attack of bacteria.

“Microtechnology can sustainably improve dental implants,” say Professor Andreas Guber and Dr. Ralf Ahrens, who head the Biomedical Microtechnology (BioMEMS) research group at KIT’s Institute of Microstructure Technology. Modern dental implants consist of a titanium screw that is fixed in the jawbone to replace the dental root, a connected abutment made of titanium for tooth replacement, and the visible dental crown. Titanium is the material of choice. It is biocompatible and ensures good growth of the screw into the bone, which is also called osseointegration. So far, optimization of dental implants has focused mainly on the titanium surface of the screw in order to further improve this process. However, dental implants may become inflamed even after successful osseointegration.

The main gateway for bacteria is the abutment. If the gum is not in perfect contact with the abutment, pockets may form, via which bacteria can reach the jawbone and cause inflammation there. In this case, the complete implant has to be removed again. The BioMEMS team now wants to solve this problem. Research is based on an optimized abutment developed by the specialist “Abutments4Life.” Grooves smaller than the width of a hair circulate the abutment and guide the cells responsible for wound healing into the right direction. In this way, wound healing is accelerated. “This system is our point of departure,” Patrick Doll, scientist of IMT, says. Further development focuses on two aspects: more precise structuring of the grooves for better guiding of the cells and search for an optimum nanosurface to which the bacteria cannot attach.

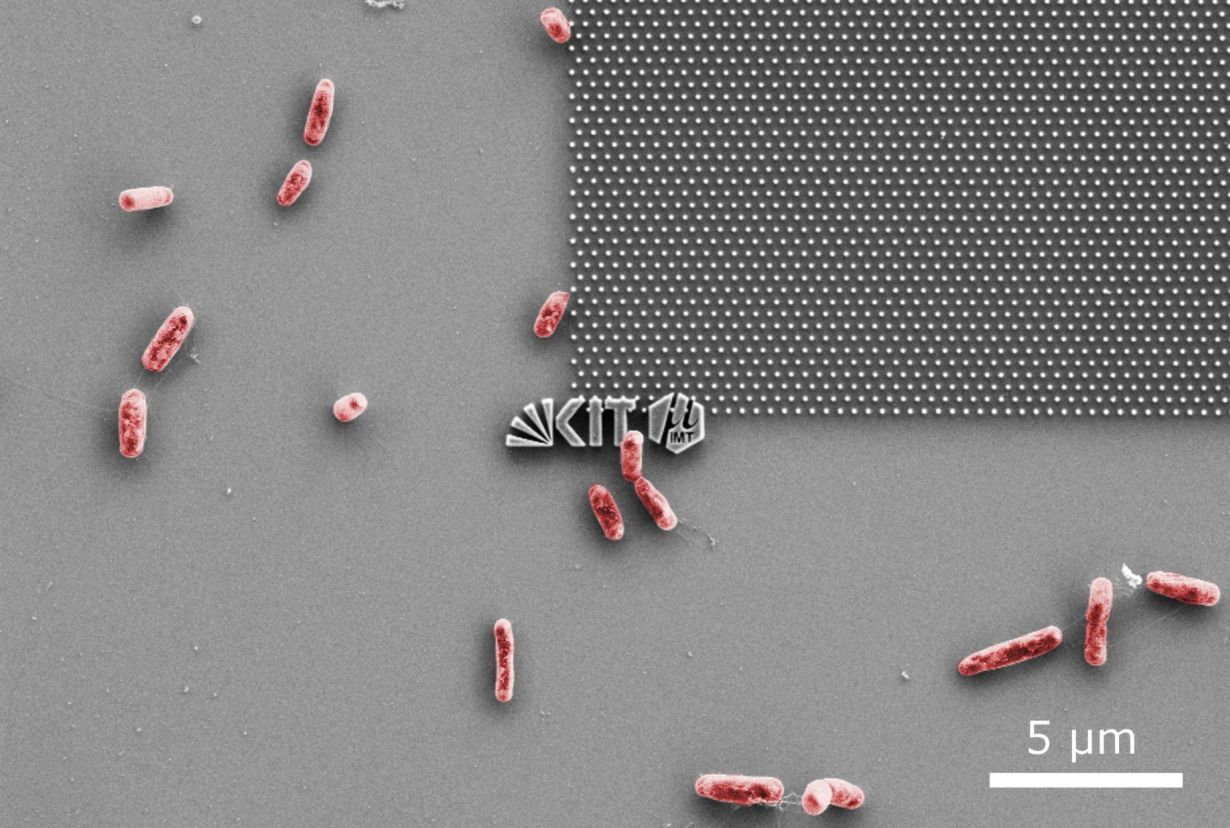

With an electron-beam lithography system, Doll produced columnar structures of 100 nanometers in diameter and 500 nanometers in height. These structures were then used to carry out adhesion experiments with typical test bacteria, such as S. aureus, E. coli or P. aeruginosa. Moreover, the structures were varied constantly. The result: depending on the distance and arrangement of the columns, adhesion of bacteria is reduced and formation of a biofilm is delayed. Hence, recovering cells have more time to close the wound, an effect that would otherwise be achieved by antibiotics only.

“We think that our structural approach is very promising,” Doll emphasizes. Production of the silicon-based nanostructures is perfect and reproducible. In the course of the project, the scientists also developed methods for use of titanium. After the first phase in the lab, preclinical tests will follow soon. Apart from dental medicine, experts see application potentials for bone plates, hearing implants, or artificial joints, among others.

The project was funded by the Federal Ministry for Economic Affairs and Energy (BMWi). Partner of the IMT was the implant producer “Abutments4Life.” Biological investigations were carried out by the Department of Operative Dentistry and Periodontology at the Medical Center – University of Freiburg.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.