Annually, more than 700,000 tons of building rubble arise during demolition work in Baden-Württemberg alone. This rubble includes large amounts of artificial mineral fibers. They are mostly hazardous to health and have to be transported to special landfills over large distances. Use of the mobile compact press developed by Karlsruhe Institute of Technology (KIT) helps protect the environment and minimize costs. The plant will be presented to the interested public during the European Week on Wednesday, May 06, 10 – 15 hrs near building 50.33 on Campus South of KIT (access Fasanengarten). Between 11.15 and 12.15 hrs, Michel-Eric Dufeil, Head, and Eva Lieber, Programme Manager of the Germany and Netherlands Unit of the Directorate-General for Regional and Urban Policy of the European Communities, will be present.

Representatives of the media are cordially invited.

Artificial mineral fibers are excellently suited for the thermal insula-tion of buildings. During demolition, however, the mineral wool causes so far unsolved problems. “Spent artificial mineral fiber products produced before the year 2000 sometimes emit fine dust that is highly hazardous to health. Hence, these materials have to be transported to special landfills and disposal facilities. Transportation distances often amount to several hundred kilometers, also in Baden-Württemberg,” Dr. Harald Schneider of the KIT Institute for Technology and Management in Construction (TMB) explains. So far, there has been no possibility to effectively compact the light material without dust pollution. When transporting artificial mineral fibers, only about 40% of the total permissible tonnage of trucks can be utilized.

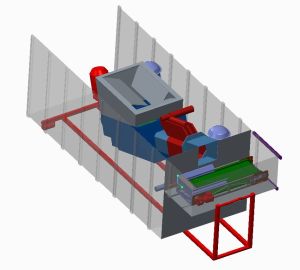

A press for compaction of artificial mineral fibers developed by the TMB in cooperation with industry partners promises to result in eco-logical and economic advantages. The scientists succeeded in inte-grating a specially constructed screw compactor into a special standardized roll-off container. “The mobile facility may be set up by disposal companies at collection points or directly near larger demolition sites,” Schneider says. He is responsible for the development of the mobile facility. In this way, disposal companies can compact the wastes directly at a ratio of more than 10:1 compared to the initial material. This does not only reduce the costs for disposal on the landfill, but also pollutant emissions during transportation. Given the fact that in Germany alone about 120,000 tons of hazardous artificial mineral fiber wastes are produced annually, the potential for reducing costs is enormous. Waste production is increasing, as many buildings insulated with artificial mineral fibers will reach the end of their service lives in the near future.

The new facility also has big advantages with respect to industrial safety and health protection. The fine dusts that are highly hazard-ous to health are removed by an integrated extraction system, such that operation takes place without any dust emission. The compac-tion product is packaged dust-proof for further shipping and trans-portation. The facility is planned to reach its maturity in the next months.

About the European Week

On the occasion of the European Day on May 09 (anniversary of the Schumann declaration 1950), the Federal States will organize a European Week in 2015 again. In Baden-Württemberg, some pro-jects financed from the European Regional Development Fund (ERDF) will have open days from May 02 to May 10.

About the Research Project

Development of the compact press for artificial mineral fibers is financed by the Baden-Württemberg Ministry of the Environment from the European Regional Development Fund (ERDF) of the European Union. Apart from the coordinating Institute for Technology and Management in Construction (TMB) of KIT, several industry partners, such as Libare GmbH, Heger GmbH & Co. KG, Dustcontrol GmbH, and Dr.-Ing. Uwe Görisch GmbH, participate in the project.

More information on ERDF funding is given at: www.rwb-efre.baden-wuerttemberg.de

More information on the open days during the European Week can be found at: www.efre-bw.de

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.