Extended use of regenerative energy sources, such as wind power and solar energy, will increase the need for systems to store large amounts of electricity. The only mature technology suited for this purpose are pumped-storage (power) stations. In Germany, they are presently providing about 7 gigawatts (GW) of power. Until 2015, a total storage capacity of 30 to 45 GW will be required. In addition, efficiency and operation safety will have to be enhanced. Engineers of Karlsruhe Institute of Technology (KIT) develop methods to optimize both power stations and water ways.

Pumped-storage power stations can respond very quickly to variable electricity production and consumption. They can balance fluctuations of wind power and solar energy as well as load peaks and times of weak load. The stations represent mature and inexpensive means to store large amounts of electricity. A storage capacity of 13 gigawatt-hours (GWh) will be provided by the pumped-storage power station of Atdorf, the turbine power being 1400 megawatt (MW). The pumped-storage power station at Vianden, Luxemburg, is presently being extended to about 1300 MW and, hence, to one of the largest pumped-storage power stations in Europe. Research activities of Thomas Mohringer from the KIT Institute for Water and River Basin Management (IWG) are aimed at optimizing such power stations in terms of efficiency and operation safety.

It is one of his objectives to extract a maximum fraction of the residual energy contained in the water flowing into the lower reservoir of a pumped-storage power station during turbine operation. At Atdorf, the upper and lower reservoirs will be connected by a gallery of nine kilometers length and nine meters in diameter – this diameter is comparable to that of a highway tunnel. Losses in such a pipeline depend on a complex interaction of water speed, swirling flow, and curvature effects. For instance, water flow in a pipeline of larger diameter is slower, as a result of which losses due to friction are reduced. “If the water, after passing the turbines, would simply flow out of the power station, much speed energy would be lost,” explains Thomas Mohringer. “A smart inlet and outlet construction will act as a diffusor: It will slow down the water gradually, convert speed energy into pressure energy, and improve the efficiency of the pumped-storage power station.”

Mohringer has specialized in the dimensioning and design of these facilities. Major components are separation pillars in the outlet section. “When the outlet pipe widens, flow often detaches from one side and flows out on the other side along the outer wall. This also produces losses. By installing a separaton pillar, however, flow is straightened. This reduces the losses and, at the same time, outflow can be controlled. I know exactly what the water does at which point. And this enhances planning safety.” In his experiments, Thomas Mohringer also found that the connection piece between the round cross section of the pipeline and rectangular cross section of the outlet area can be optimized by widening. Flow is slowed down and losses are reduced. In this way, total efficiency of pumped-storage power stations can be improved. “Efficiency will be enhanced by about 0.1% only. But considering the enormous power of these stations, optimization at a turbine power of 1400 MW will increase the power available by 1.4 MW, without additional costs being incurred. This corresponds to the power of a wind power plant. No additional expenditure is needed, power is increased simply by a smart design. In addition, operation safety is enhanced by the more homogeneous flow in the system,” emphasizes Mohringer.

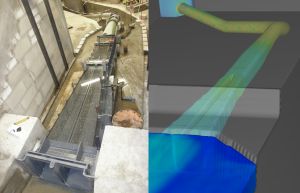

The hydraulic engineer studied various shapes and positions of pillars as well as different cross sections and outlet angles of the pipeline. He performed experiments using a physical model at the hydrological laboratory and carried out numerical simulations. By means of hybrid modeling, the advantages of both methods can be used and the results compared. “In the physical model, I have a real flow and a real result. Using a numerical model, I can work on the natural scale without spatial constraints and achieve a high data density.” Among others, comparison of speed measurements and numerical data revealed an excellent agreement. The optimization approach is aimed at further developing numerical calculations such that engineers doing planning work in the future will only have to check the results in the physical model instead of having to measure all results in experiments that are associated with a high expenditure.

The KIT Climate and Environment Center develops strategies and technologies to secure the natural bases of life. For this purpose, 660 employees of 32 institutes produce fundamental and application-oriented knowledge relating to climate and environmental change. It is not only aimed at eliminating the causes of environmental problems, but increasingly at adapting to changed conditions.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.