Germany has hardly any natural resources, but it is one of the biggest clay-extracting countries worldwide. This domestic resource is indispensable for a number of industrial products, such as cement, car tires or toothpaste. Scientists of the Competence Center for Material Moisture (CMM) and the Institute of Functional Interfaces (IFG) of Karlsruhe Institute of Technology (KIT) study how this mineral material can be used efficiently.

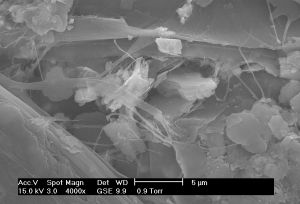

“In the foreseeable future, clay will be available in sufficient amounts. Still, it should be used efficiently,” says Dr. Rainer Schuhmann, Deputy Head of the IFG and Head of the CMM. If clay exists, it may not always be available for use. Clay-containing soils store water. Frequently, they represent humid biotops and landscape conservation areas. To reduce the consumption of resources, KIT researchers now search for the optimum clay for an application, as clays differ considerably. “Clay consists of five to ten minerals,” explains Private Lecturer Dr. Katja Emmerich, CMM/IFG. Interaction of these minerals with each other and with water may cause the clays to react in many different ways when they are processed. An example is bleaching. In paper production, clay is added to make the paper stable enough for printing. Although clay from the same deposit is contained, some papers are “whiter” than others. The reason: “Bleaching efficiency of the clay-containing paper depends on the type of clay mineral in which the iron is bound,” explains Emmerich. Based on this knowledge, the bleaching process can be adapted to the clay material and less water is subjected to chemical pollution.

Based on reliable predictions of the behavior of a certain clay, suitable materials can be recommended to industry for their products. The scope of applications is wide: Clay is used for ceramics and for the fabrication of molds used for metal casting. Clay is applied to seal landfills and stabilize walls when constructing tunnels. KIT scientists think that resource assessment by scientific analysis will allow for “producing better products more quickly and efficiently.” So far, clay has been selected by processing companies according to experience, i.e. depending on its appearance or properties while it is kneaded or its general chemical composition, Katja Emmerich says. “Now, we do no longer consider clay as a whole, but its solid, liquid, and gaseous components in their complex interaction,” says the mineralogist. Research is aimed at understanding how the structure of the clay and its properties are related. These findings will also reduce emissions. By controlling the combustion process in ceramics production, fluorine can be bound minerally and its emission is reduced.

As clay cannot be recycled, sustainability can only be achieved by efficient use. The CMM, where Katja Emmerich heads the Division of Applied Mineralogy, has established the Alliance for Clay Research (ART) together with the Forschungsinstitut für Anorganische Werkstoffe – Glas/Keramik – GmbH (FGK) (Research Institute for Inorganic Materials – Glass – Ceramics) at Höhr-Grenzhausen. In this alliance, CMM and IFG conduct fundamental research, while FGK is in charge of applied research and development. Together with partners from industry, associations, and authorities, the Alliance is aimed at enhancing research into industrial minerals and opening up further applications.

The KIT Climate and Environment Center develops strategies and technologies to secure the natural bases of life. For this purpose, 660 employees of 32 institutes produce fundamental and application-oriented knowledge relating to climate and environmental change. It is not only aimed at eliminating the causes of environmental problems, but increasingly at adapting to changed conditions.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.