Engines with direct fuel injection emit ultrafine soot particles. Two subprojects of the collaborative research center “Non-stationary Combustion” are dedicated to investigate this process in order to counteract particle emission. For this specific purpose, KIT scientists have developed a new laser diagnostic technique.

Fine dust regulations and green environmental zones have pushed the issue of fine dust emissions into the public focus. In particular, a major fraction of ultrafine particles is released into the environment in the form of soot particles with the exhaust gases of Diesel- and spark ignition- engines. These ultrafine particles, having diameters less than a 10,000th of a millimeter, may deeply penetrate into the lungs and impair human health.

In modern Diesel- and also in spark ignition- engines, the fuel is injected at high pressure directly into the combustion chambers of the cylinders to optimize fuel efficiency. During combustion, fuel-rich zones are formed in the vicinity of the fuel jet. In these zones, soot particles are formed. If these particles, which are preliminarily formed in an early phase of combustion, are not completely oxidized during the ongoing combustion cycle, they are released into the environment with the exhaust gas of the engine. Particulate filters in Diesel vehicles largely prevent particle emission, but increase vehicle costs and fuel consumption.

Within two interdisciplinary subprojects of the collaborative research center 606 “Non-stationary Combustion: Transport Phenomena, Chemical Reactions, Technical Systems”, of which the spokesman is Professor Henning Bockhorn, scientists at KIT investigate the formation and oxidation of soot in combustion engines with direct fuel injection. Modern laser diagnostic techniques are used to determine soot concentration, particle sizes, and particle number densities in optically accessible combustion chambers.

Based on the findings obtained from these investigations, soot emission of engines can be influenced and particle emission can be counteracted. Moreover, the experimental results are used to develop and validate mathematical models which quantitatively describe the physical and chemical processes involved in the formation and oxidation of soot. “In future, such models might be used for the development of new engines to simulate the behavior under various operation conditions,” explains one the project heads involved, Professor Rainer Suntz from the KIT Institute for Chemical Technology and Polymer Chemistry, “Compared to experimental studies, much time and costs can be saved.”

For their studies, KIT researchers have developed a new laser diagnostic technique. Two successive laser pulses induce several measurement signals within a 10 millionth of a second. Thus, it is possible to determine two-dimensional maps of soot concentration, particle sizes, and number of particles in the combustion chamber of a single cylinder of the engine with high spatial and temporal resolution.

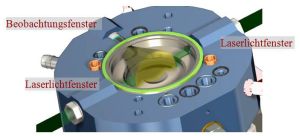

Engine with optical access: Using laser diagnostic methods, the concentrations of soot particles and the spatial distribution can be measured directly in the combustion chamber. (Photo: Institut für Kolbenmaschinen, KIT).

Beobachtungsfenster = detection window

Laserlichtfenster = Laser light window

The measurements in spark ignition engines reveal a more or less strong soot formation directly above the surface of the piston. Whereas in the volume of the combustion chamber itself, relatively low soot concentrations are observed. The soot particles above the piston surface originate from so-called pool-fires. The latter are burning fuel puddles formed by a wetting of the piston during fuel injection shortly before top dead center. The liquid fuel on the surface of the piston is combusted comparatively late in the combustion cycle, because it has to be heated sufficiently by the combustion taking place in the gas-phase. Moreover, the temperatures of these pool-fires are relatively low, as fuel evaporation and high thermal conductivity of the aluminum piston draw much heat from the combustion process. As a result, time and temperature are not sufficient for the complete oxidation of the soot particles formed by the pool-fires. Therefore, they are emitted with the exhaust gas of the engine.

Karlsruhe Institute of Technology (KIT) is one of Europe’s leading energy research establishments. The KIT Energy Center pools fundamental research with applied research into all relevant energy sources for industry, households, services, and mobility. Holistic assessment of the energy cycle also covers conversion processes and energy efficiency. The KIT Energy Center links competences in engineering and science with know-how in economics, the humanities, and social science as well as law. The activities of the KIT Energy Center are organized in seven topics: Energy conversion, renewable energies, energy storage and distribution, efficient energy use, fusion technology, nuclear power and safety, and energy systems analysis.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.