In an interdisciplinary project, KIT researchers have succeeded in developing a new type of optical resonators. These novel microcavities are particularly efficient laser light sources due to the shape and smooth surfaces of their polymer structures. In addition, they have the potential of detecting smallest biomolecules, viruses, or hazardous substances.

Optical microresonators allow confinement and storage of light in a space with dimensions smaller than the diameter of a hair. Using them, fundamental optical and quantum-physical effects can be analyzed. Confinement of light in microresonators is based on the simple principle of total reflection: Light is reflected from the resonator surface to be entrapped in the interior. The beams of light run along the edge of the resonators to be stored there for a long time and create an optical “whispering gallery” with a high optical quality. The principle can be compared with that of the sound waves traveling along the circumference of the dome of St. Paul’s Cathedral in London.

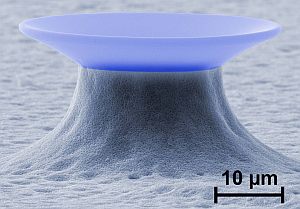

Together, the KIT research group headed by Professor Heinz Kalt at the Institute for Applied Physics (APH) and at the Center for Functional Nanostructures (CFN), and the independent junior research group, headed by Dr.-Ing. Timo Mappes at the Institute for Microstructure Technology (IMT), have succeeded in producing novel conical microresonators by applying a specially developed thermal reflow process. The microcavities consist of polymers and have diameters of 40 µm (which is approximately 1/3 of the diameter of a hair). Their high performance and efficiency are due to the extreme smoothness of the polymer surfaces.

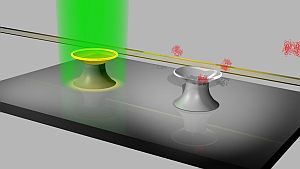

Lab-on-chip system with micro cone laser pumped optically with a green laser (left);

Micro cone resonator as biomolecule detector (right). (Source: Institute for Microstructure Technology, young investigator group headed by Dr.-Ing. Timo Mappes)

There are two major applications: The micro cones developed can be used as novel laser light sources or as extremely sensitive detectors in label-free hazardous-substance or biomolecule detection. Since label-free identification can do without the tedious procedure of chemical or biological sample preparation (no additional markers such as fluorescent dyes or nanoparticles are being attached), it has particular advantages and is more favourably priced and faster than many of the well-established methods.

The researchers now aim to integrate the light source and detector on a chip to obtain highly compact so-called lab-on-chip systems for future applications.

The high resonator quality has still another decisive advantage: „The use of micro cone lasers in components is made very attractive by operating lasers at low power,” says physicist Tobias Großmann, who is member of both research groups at KIT and holds a scholarship grant at the Karlsruhe School of Optics and Photonics (KSOP). For light amplification, the researchers incorporate organic dyes in the polymer cavities. By adapting the concentration of the dyes, the emission wavelengths of the lasers can be changed, and the color of the laser can be adjusted as desired.

The enormous potential for future industrial applications of the developed micro cone resonators includes high-sensitivity label-free molecule detection, optical data transmission filtering, and the use of resonators as sources for the generation of non-classical light, which is a basis for future quantum computers.

Since KIT researchers use the mass production methods that are applied by the semiconductor industry, they enable the manufacture of micro cones in series in the medium term.

Bibliography

[1] Tobias Grossmann, Mario Hauser, Torsten Beck, Cristian Gohn-Kreuz, Matthias Karl, Heinz Kalt, Christoph Vannahme, and Timo Mappes, High-Q conical polymeric microcavities, Appl. Phys. Lett. 96, 013303 (2010)

[2] Tobias Grossmann, Simone Schleede, Mario Hauser, Mads Brøkner Christiansen, Christoph Vannahme, Carsten Eschenbaum, Sönke Klinkhammer, Torsten Beck, Jochen Fuchs, G. Ulrich Nienhaus, Uli Lemmer, Anders Kristensen, Timo Mappes, and Heinz Kalt, Low-threshold conical microcavity dye lasers, Appl. Phys. Lett. 97, 063304 (2010)

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.