“In the 1990s, we developed the Soft Kill Option SKO, a method for the design of lightweight and still strong components,” explains Professor Dr. Claus Mattheck, head of the Biomechanics Division of the Institute for Materials Research II of Karlsruhe Institute of Technology. “This method was modeled on phagocytes that remove superfluous parts of bones. Non-carrying sections were eliminated. The remaining section is the framework proper that carries the weight.”

Since then, various types of the Soft Kill Option have been used by industry. Apart from the corresponding software, it requires high computation powers. Now, this method shall be replaced by a computer-free tool, the “Force Cone Method”.

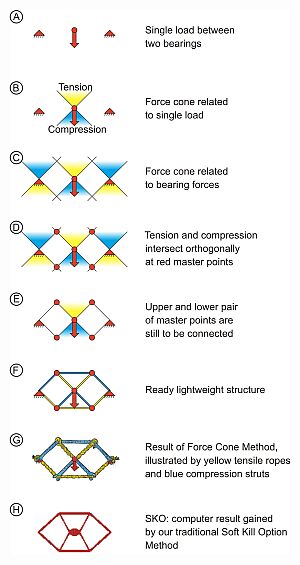

”The basic idea is that in elastic space, a 90-degree compression cone is pushed and a tension cone is pulled by any force,” describes Mattheck his new method. “The input data are the load and the fixations of the future component, which result from its function.”

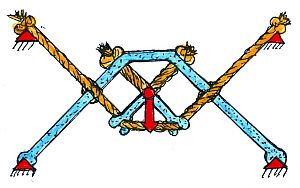

Design with the force cone method

(Figure: KIT)

Construction with the Force Cone Method starts with the user drawing the compression and tension cones. At the points, at which tension and compression beams of these cones intersect orthogonally, mostly at the cone edges, so-called master points are located. These are preferred connection points of compression struts and tension ropes, of which the component is composed.

From the drawing with ropes and struts, even the layman without any mechanical knowledge can derive the force flows. This makes the tool interesting for teaching and formula-free design.

Comparative calculations with the SKO method were in impressing agreement with the graphical results of the Force Cone Method.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.