For the development of innovative battery systems, reliable real-world safety tests of the lithium-ion cells in use are required. In the ProLIB research project, the Karlsruhe Institute of Technology (KIT) now collaborates with testing and standardization institutes and partners from industry in order to develop improved standards that are intended to ensure greater safety but also more flexibility in battery design. The German Federal Ministry for Economic Affairs and Energy funds this research with more than 1.2 million euros.

If you can't remember the last time you found your notebook pierced by a nail, rest assured that this indeed happens very rarely. Nevertheless, this is precisely the procedure commonly used today for safety testing of lithium-ion batteries: “In order to perform certain tests, the cells must first be massively mistreated,” says Dr. Anna Smith from the Institute for Applied Materials (IAM) of KIT. “The objective of these efforts is to trigger assumed worst-case defects inside the cells in order to observe what will happen inside the battery." Besides piercing the cell cells with nails, it is also common practice to subject the cells to extreme overcharging or overheating.

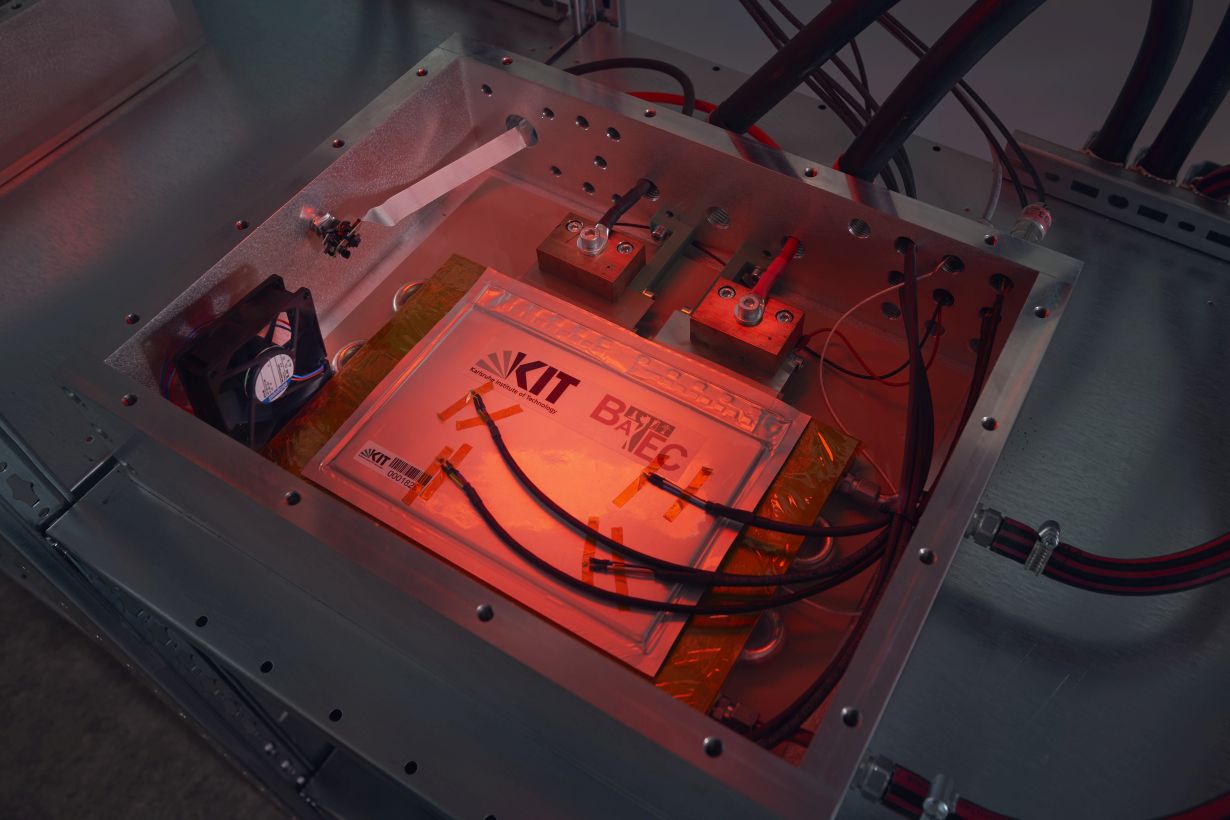

The discrepancy existing between these test methods and a realistic load does have its consequences: The actual error behavior is not the subject of the tests, and thus, manufacturing defects of cells of inferior quality and their risks remain undetected, while actually safe cells are underrated. “If battery systems are designed for unrealistic worst-case scenarios, they will not become safer but bulkier, heavier, less sustainable and also more expensive than necessary,” states Anna Smith. Her team at the Battery Technical Center of KIT collaborates with its partners, AVL Deutschland GmbH, CTC advanced GmbH, and TÜV Rheinland LGA Products GmbH as well as with the associated partners ads-tec Energy GmbH, Intilion GmbH, Jungheinrich Norderstedt AG & Co. KG, Solarwatt Innovation GmbH, VARTA Storage GmbH, and VDE|DKE (Deutsche Kommission Elektrotechnik Elektronik Informationstechnik in DIN und VDE) within the scope of a project that is funded with more than 1.2 million euros by the German Federal Ministry for Economic Affairs and Energy. The project is called “Entwicklung eines Propagations-Prüfverfahrens für Lithium-Ionen-Zellen in Batteriesystemen” (ProLIB, development of a propagation test method for lithium-ion cells in battery systems) and it is aimed at developing more realistic safety standards and tests.

More safety through more realistic test methods

In principle, the concerns about dangerous defects in lithium-ion cells are not unjustified as dendrites, i.e. spiky lithium deposits, can form on the anode. The probability that these will then trigger short circuits, and thus ultimately cause a thermal runaway (this is an exothermic reaction with a fast, self-accelerating heat build-up), is particularly high in cells that contain lower-quality components. The propagation of this fault to neighboring cells results, in the worst case, in a chain reaction. This, in turn, might cause the battery to catch fire. Any increase in energy density, for example, to extend the cruise range of an all-electric car or to improve sustainability by employing less raw materials, is impaired by the use of test methods that are way too coarse. “There is far too little focus on the resistance of the lithium-ion cell to really dangerous defects, which can vary greatly between manufacturers due to the cell design or the cell components, for example. Starting with the thermal runaway criterion is like measuring the safety of a household lighter solely by its explosion behavior,” says Anna Smith.

Research is currently underway worldwide to improve propagation tests. In other research projects, however, the focus is on triggering a thermal runaway in a manner that is easier to reproduce (e.g. with a laser) – regardless of whether a cell would actually experience it in practice. ProLIB is so far the only research project where real-world and cell-specific faults are investigated. Now, an improved test method for new standards on lithium-ion batteries in stationary and mobile applications will be developed in order to close the existing gaps in the standards with regard to realistic evaluation criteria for the safety and quality of lithium-ion batteries. The new standards will enable a fairer competition, help reduce raw material input, development and product costs by avoiding over-design, and improve the operational safety of lithium-ion batteries.

Read more about the Battery Technical Center: https://www.batterietechnikum.kit.edu/

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.