The Federal Ministry of Education and Research (BMBF) intends to advance battery research in Germany with four new clusters of competence. The Karlsruhe Institute of Technology (KIT) is involved in all four clusters, with a coordinating function in two of them: InZePro (intelligent battery cell production) focuses on flexible production systems, AQua (analytics/quality assurance) aims at improving the performance and service life of batteries. To receive funding for the clusters, the participating researchers now first submit full proposals.

“Powerful and safe battery technologies are the main prerequisite for achieving the energy turnaround and for shaping sustainable mobility,” says the President of KIT, Professor Holger Hanselka. “The clusters take up the most central aspects of this – agile production systems, recycling, utilization concepts, and quality assurance. We are very much looking forward to pooling our expertise with the partners in all four clusters and advancing battery research.”

InZePro cluster of competence (intelligent battery cell production)

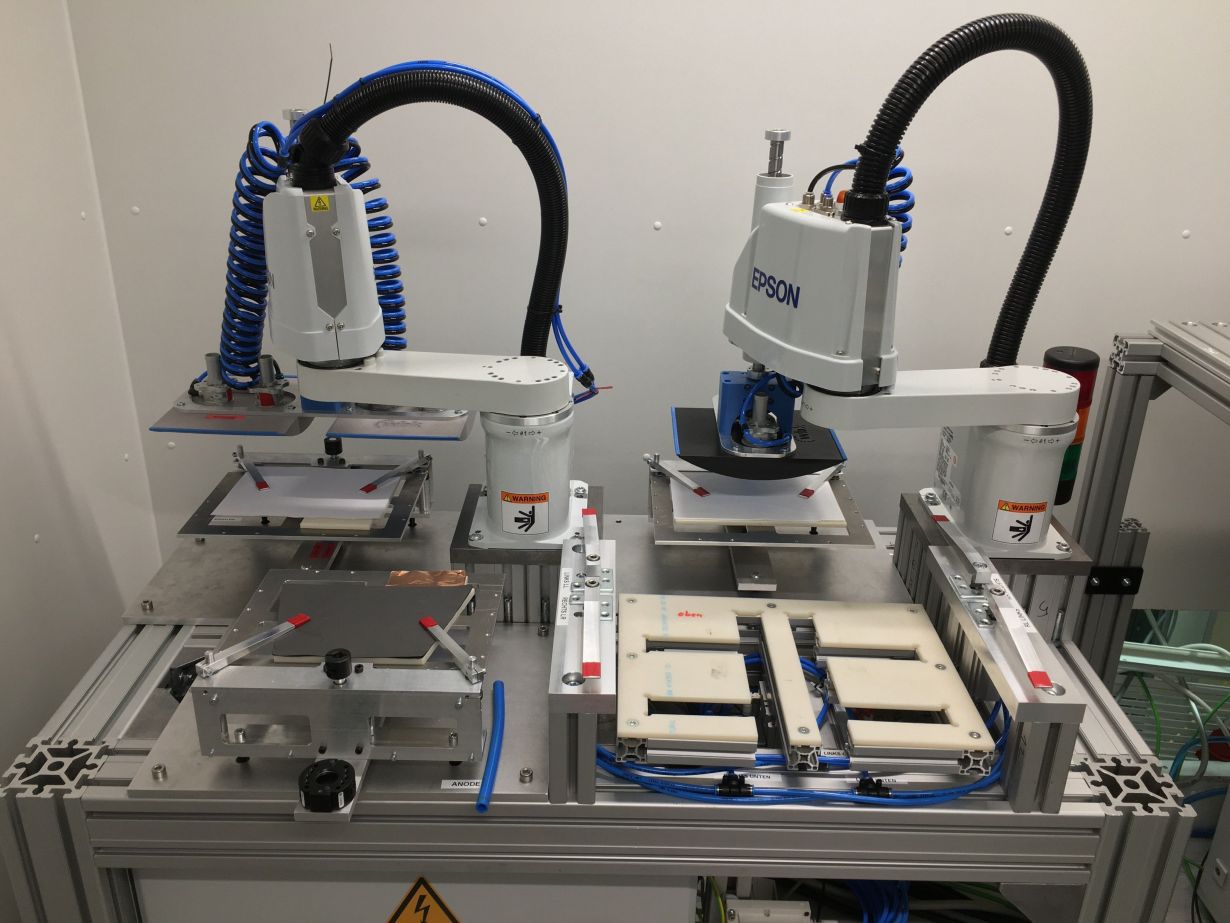

The focus of the InZePro (intelligent battery cell production) cluster of competence is on agile and flexible plant technology – by means of which battery cells can be produced with flexibility in terms of variants and quantities – the digitization of individual plants and the entire production system, and on virtual production systems and the use of AI in production. “The aim is to produce a wide variety of battery cell variants in small to large quantities using flexible, automated and intelligent production systems optimized by artificial intelligence. In this way, we want to ensure that manufacturers, for example in the automotive industry, can increase their productivity even in times of a volatile order situation and high product variance,” explains Professor Jürgen Fleischer, head of the wbk Institute of Production Science, who represents the KIT in the InZePro coordination team. The cluster is expected to receive a total of around 30 million euros in funding.

AQua cluster of competence (analytics/quality assurance)

The aim of the AQua cluster is to improve the performance of lithium-ion batteries while ensuring a long service life. As a basis for quality assurance in production, the scientists are developing analy-tical methods and standards that consider the complex processes taking place in a battery. “In AQua, we want to develop a comprehensive and cross-process understanding of how the interaction of materials, production steps, and specific electrochemical behavior affects the structures and properties of the battery,” explains Professor Helmut Ehrenberg of KIT, who is on the coordination team. This cluster is expected to receive a total of around 20 million euros in funding.

Boosting battery research in Germany

KIT is represented in the coordination teams of the InZePro and AQua clusters. KIT researchers indeed also participate in the two other clusters, i.e. greenBatt (recycling/green batteries) and BattNutzung (battery utilization concepts). The new clusters are scheduled to start their work in October 2020. In addition, KIT is involved in the FestBatt cluster of competence for the development of solid-state batteries, which has already been running since 2018, and in ProZell for battery cell production since 2016.

The clusters tie in with the successful battery research at KIT, such as the CELEST platform jointly founded with the University of Ulm and the ZSW (Center for Solar Energy and Hydrogen Research Baden-Wuerttemberg).

The competence clusters are part of the “Forschungsfabrik Batterie (Battery Research Factory) master concept and are meant to contribute to strengthening battery research in Germany along the entire value chain. The BMBF invests another 100 million euros in battery research at universities and non-university research facilities.

Find more information at: https://www.bmbf.de/de/karliczek-deutschland-ist-heute-wieder-hotspot-12069.html

More about the KIT Energy Center: http://www.energie.kit.edu

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.