In the past years, industry developed resins with novel properties by means of nanotechnologies. Such resins may be microwave-active, which means that they can be cured by microwave irradiation. The HEPHAISTOS technology developed at KIT can be used to rapidly, homogeneously, and efficiently produce large and thick glass fiber structures. First prototypes of this black glass fiber material were produced recently by KIT.

Everybody knows the story of Daedalus and Icarus: Icarus approached the sun too closely and fell down, because the glue of the wings was molten. The problem of Daedalus and Icarus still is important in modern aircraft research. Planes are increasingly constructed from plastics-like materials and use of the correct “glue” is of big importance. This hardened glue must keep the plane, fuselage, and wing structures together.

“Over many years, we gathered experience in the microwave curing of carbon fiber composites,” explains Dr. Lambert Feher, who heads the Industrial Microwave Technology Group of the Institute for Pulsed Power and Microwave Technology of Karlsruhe Institute of Technology (KIT). “Thanks to a large project funded by the Federal Ministry of Education and Research (BMBF), we have now transferred this experience to glass fiber structures.”

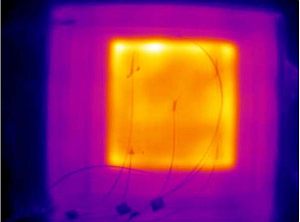

Using nanotechnological materials, industry succeeded in producing novel microwave-active resin systems. With the HEPHAISTOS technology developed by KIT, large and thick glass fiber structures have now been cured for the first time in a rapid, homogeneous, and efficient manner by an industrial microwave process. The process was developed by KIT scientists from the Institutes for Pulsed Power and Microwave Technology, Technical Chemistry, and Materials Research in cooperation with partners from BASF AG and Hexion Specialty Chemicals Inc.

The HEPHAISTOS technology allows for completely new applications in aviation, the use of wind power, boat construction, construction materials technology, and automotive engineering. This opens up novel production options and considerable cost reduction potentials in the production of glass fiber compounds.

Karlsruhe Institute of Technology (KIT) is one of Europe’s leading energy research establishments. The KIT Energy Center pools fundamental research with applied research into all relevant energy sources for industry, households, services, and mobility. Holistic assessment of the energy cycle also covers conversion processes and energy efficiency. The KIT Energy Center links excellent competences in engineering and science with know-how in economics, the humanities, and social science as well as law. The activities of the KIT Energy Center are organized in seven topics: Energy conversion, renewable energies, energy storage and distribution, efficient energy use, fusion technology, nuclear power and safety, and energy systems analysis.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.