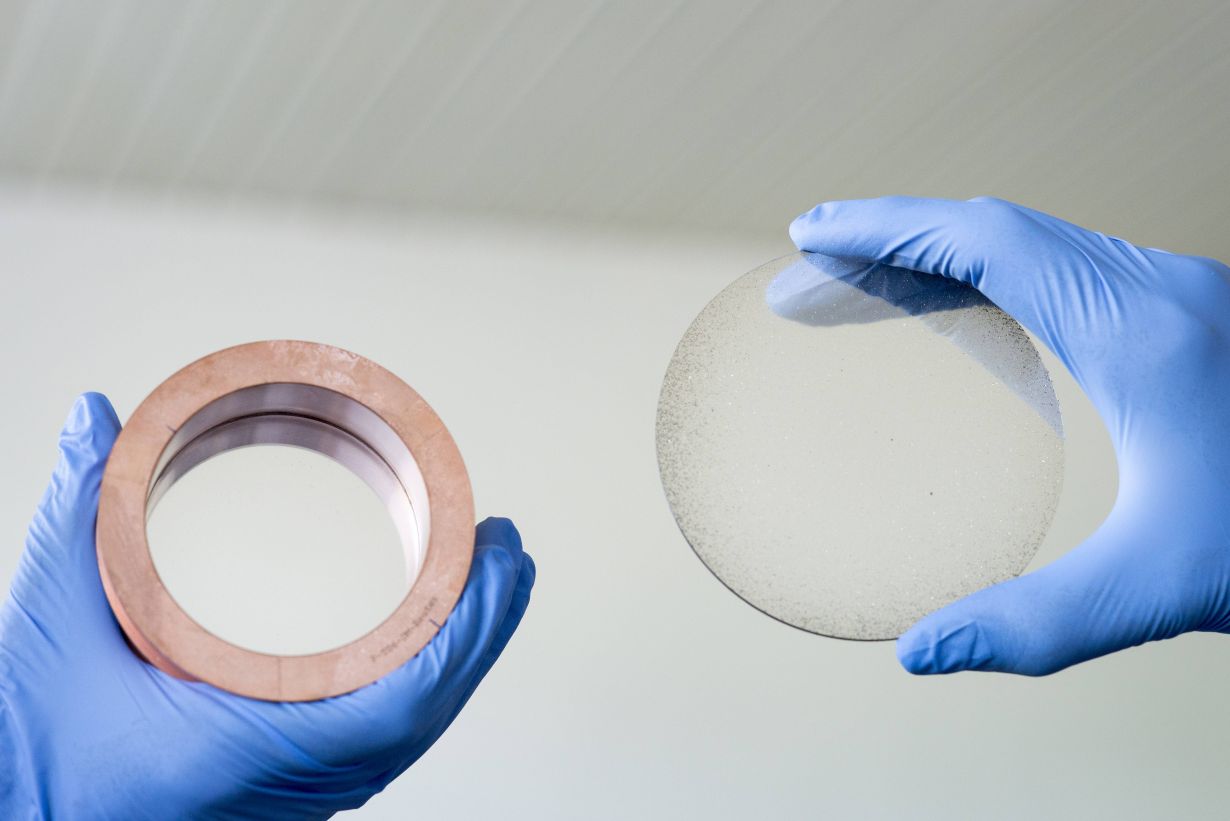

Fusion power plants promise nearly unlimited climate-friendly energy and scientists worldwide cooperate to reach this goal. A little known aspect of this highly specialized field of research concerns diamond which is in fact an indispensable material for fusion technology. Researchers of Karlsruhe Institute of Technology (KIT) develop diamond disks for window units to heat the plasma in fusion reactors. In cooperation with a company called Diamond Materials, they have now produced a diamond disk of 180 mm in diameter.

It happens in the fire of the sun: hydrogen atoms are fused to helium and in the course of this nuclear fusion reaction, gigantic amounts of energy are released. In fusion power plants on Earth, this “starfire” might one day contribute to sustainable and secure energy supply. Worldwide, fusion researchers cooperate to take the first reactors into operation. At KIT, so-called gyrotrons are developed for the ITER research reactor and smaller reactors, such as Wendelstein 7X and ASDEX Upgrade. Gyrotrons are microwave oscillators generating a temperature of up to 150 million degrees Celsius in the reactor, similar to a very big microwave. This high temperature makes the tritium fuel reach the plasma state required for fusion. To guide microwave radiation from the gyrotrons into the plasma and in order to maintain a vacuum and keep the radioactive tritium inside the reactor, a team around Dr. Dirk Strauss and Professor Theo Scherer of KIT’s Institute for Applied Materials (IAM) designs appropriate window units. For the disks, only one material is suited: “diamond is indispensable,” says Dirk Strauss. “No other known material survives the extreme microwave radiation and, at the

same time, has the required permeability with low losses.”

Professor Theo Scherer (left) and Dr. Dirk Strauss of KIT’s Institute for Applied Materials (IAM) with the diamond disks. (Photo: Tanja Meißner, KIT)

To guide radiation of more than one megawatt power into the ITER research reactor, numerous diamond windows have been designed by IAM and produced in cooperation with industry partners. Meanwhile, scientists are also working on window units for ITER’s successor called DEMO, in which power will be produced from 2050 onwards. As a consequence of planned multi-frequency operation of the microwave heating system in DEMO, however, new types of gyrotrons will be required. They are presently being developed by the research team of Professor John Jelonnek at KIT’s Institute for Pulsed Power and Microwave Technology. These new gyrotrons will need new window units with larger diamond disks. The corresponding prototype is now available. “Our disk has a diameter of 180 mm and is up to 2 mm thick,” says Theo Scherer. “This makes it the biggest synthetic diamond structure ever produced ready for use.” Now, IAM is examining the surface structure and high-frequency characteristics with respect to microwave losses of the window.

The disks are made of synthetic diamond by chemical vapor deposition (CVD), a special coating technique. The CVD diamonds grow on a silicon surface in a small vacuum reactor filled with a gas mixture. By means of microwave irradiation, this mixture is turned into a plasma, similar to what happens in a fusion reactor, but with much smaller energy consumption. The plasma consists of atomic hydrogen that prevents undesired graphite formation and a small amount of methane that supplies carbon for the diamond. “It is a time-consuming and very complex process,” Dirk Strauss says. “The diamond window grows a few micrometers per hour.” The end product is accordingly expensive. Production of a diamond disk for the DEMO reactor costs a six-digit amount, Strauss says.

However, the options of using diamond material in fusion technology are not yet exhausted. So far, diamond disks with a polycrystalline structure have been designed at IAM. These disks consist of a number of small diamonds. “At the moment, we are working on the development of monocrystalline diamond disks,” Theo Scherer says. “This might further reduce microwave losses during transmission.”

More about the KIT Energy Center: http://www.energie.kit.edu

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.