At ACHEMA 2018, the leading international trade fair for the process industry in Frankfurt am Main from June 11 to 15, Karlsruhe Institute of Technology (KIT) will be showcasing innovations for future energy supplies and process engineering. The KIT booth (Hall 9.2, booth A80) will introduce the Energy Lab 2.0 research infrastructure, show micro-structured reactors for the production of carbon dioxide neutral fuels, present additive manufacturing for the production of complex components for process intensification, and demonstrate data from computational fluid dynamics simulations using a virtual reality visualization approach.

KIT will introduce the following topics at ACHEMA 2018:

Energy Lab 2.0

In Energy Lab 2.0, KIT examines the interaction of important components of intelligent energy networks based on renewable sources together with the Jülich Research Center (FZJ) and the German Aerospace Center (DLR). The real-life lab consists of a network of facilities and a simulation platform. This allows Energy Lab 2.0 to link the generation of electricity from renewable sources with different storage concepts. In addition to storing the electricity in large battery systems, the focus is above all on its conversion into liquid or gaseous chemical energy sources via hydrogen in combination with carbon dioxide or syngas from biogenic waste. Energy Lab 2.0 also examines the storage of renewable electricity in the form of high-temperature heat as well as reconversion of the generated chemical energy sources. This means that the links between the electricity, heat and fuel sectors can be thoroughly tested in Energy Lab 2.0. Researchers are also working on innovative methods and hardware components for stabilizing the power grid and on the secure information and data networks required for that.

Carbon dioxide neutral fuels from renewable electricity

KIT examines processes in Energy Lab 2.0 which can be used to sustainably produce synthetic hydrocarbons from carbon dioxide and electricity generated from renewable sources. These power-based synthetic hydrocarbons will not only serve as carbon dioxide neutral fuels and materials for many chemical products in the future, but will also support the storage and distribution of electricity from fluctuating renewable sources. For efficient decentralized fuel synthesis, researchers use microstructured chemical reactors from INERATEC GmbH, a spin-off from KIT. The modular design allows for the complete process chain to be implemented in standard freight containers, making them mobile and flexible. In Energy Lab 2.0 two container-based synthesis systems are currently being developed which scientists will use to test new technologies for the production of synthetic natural gas (power-to-gas) and liquid fuels (power-to-fuel) from electricity and carbon dioxide.

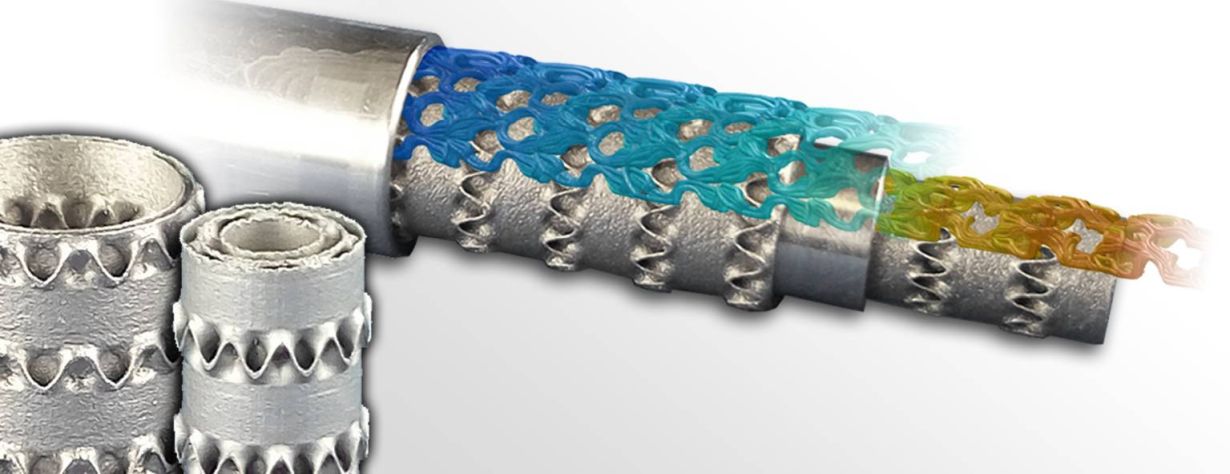

Additive manufacturing of flow guide elements

Researchers at KIT have developed flow guide elements which enable accurate guiding of a flow with minimal loss of pressure. This makes it possible to achieve customized and optimized heat transfer as well as improved material transfer in catalysis. The complex geometries of these flow guide elements can be easily created through additive manufacturing. A non-solid source material such as a powder, a suspension or a solution is solidified in layers with spatial resolution. This creates a three-dimensional component layer by layer. Additive manufacturing has several advantages compared to conventional production methods such as casting or machining. It enables highly efficient use of materials, a wide range of design options, application-optimized design, and rapid and cost-effective production of prototypes. This opens up new opportunities for intensifying chemical and process-engineering activities.

Virtual reality visualization of three-dimensional data from computational fluid dynamics simulations

Virtual reality (VR), displaying and perceiving a computer-generated virtual environment, is taking over more and more areas, including process engineering. KIT researchers use virtual reality to prepare and evaluate three-dimensional data from computational fluid dynamics (CFD) simulations. CFD supports the development and optimization of process-engineering machines and systems. The use of VR enables intuitive exploration of data even with complex geometries and turbulent flows. KIT researchers will demonstrate the VR concept for different applications, for example for visualizing the flow field and the associated temperature distribution of the air flow in a refrigerated truck.

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.