Exploration of new energy carriers and interim storage of sustainable energies are two big challenges of the Energiewende, the transformation of the energy system. At its ACHEMA booth (9.2 D67) in Frankfurt, KIT will present latest processes for this purpose from June 15 to 19, 2015. With these processes, straw and algae can be used as feedstocks for fuel production, utilization of energy-rich gas is improved, or manufacture of battery electrodes is accelerated.

Bioliq: High-quality Fuels from Residual Biomass

The bioliq (biomass to liquid) process accounts for the fact that straw and other biogenous residues arise in a widely distributed manner and have a low energy content. Bioliq has been developed to allow for an economically efficient large-scale production of fuel. First, the dry residual biomass is converted into a crude oil-like substance of high energy density by flash pyrolysis. This so-called biosyncrude can be transported efficiently over long distances for centralized conversion into customized fuels or basic chemical products. A close-to-industry pilot plant in Karlsruhe is already producing gasoline of high quality – fully equivalent to conventional gasoline and compatible with the environment. The output of the pilot plant is about 1 t of fuel per day. As the bioliq process uses straw and other biogenous residues that do not require any additional cultivation areas, it does not compete with food or feed production. At the KIT booth, the complete four-stage bioliq process will be explained.

More information:

http://www.kit.edu/kit/english/pi_2014_15980.php

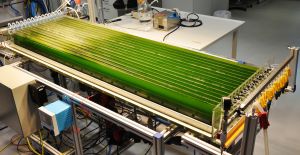

Horizontal Bioreactors for Microalgae

Microalgae are promising sources of animal feed, food, and biofuels of the third generation. Based on microalgae, various compounds, such as carbohydrates, lipids, and proteins, can be produced. Microalgae can be cultivated in freshwater, salt water or waste water. Low-cost and low-energy growth of algae requires the development of new photobioreactors and the optimization of existing strategies for process conduct. At KIT, horizontal photobioreactors of transparent zig-zag structure were developed and patented. They are characterized by low material costs, low hydrostatic pressure, and high light dilution. The surface structure and the small layer thickness ensure homogeneous light distribution and a high surface to volume ratio. Incident light at low angles is reflected to opposite surfaces. In this way, light utilization is enhanced. The functioning prototype bioreactor will be presented at the KIT booth for detailed insights into the development.

More information:

http://bvt.blt.kit.edu/english/mitarbeiter_bvt_682.php

Slot Dies Coat Lithium-ion Battery Electrodes

About 40% of the costs of a lithium-ion battery are caused by the manufacturing process and in particular by electrode production. To produce electrodes, pastes on carrier foils are coated. Best battery properties are achieved by intermittent coating, in the case of which process speed is limited to about 25 to 30 m per minute. A newly patented process of KIT now allows to reach speeds of about 100 m per minute. This results in major cost reductions during battery production. At the KIT “Coating & Printing Lab”, it was demonstrated on the pilot scale that this new slot die technology requires very few movable parts only and still reaches excellent layer qualities with sharp start and stop edges and clean gaps. At the KIT booth, experts will explain the fundamentals of this new process based on the slot die displayed there.

More information:

http://www.kit.edu/kit/english/pi_2014_15826.php

High-quality Fuels from the High-tech Container

Work of the KIT spinoff Ineratec is aimed at designing, constructing, and selling turnkey container-based compact facilities for the decentralized conversion of natural gas and biogas into valuable products that can be stored. Depending on the source of the gas, it is possible to produce nearly greenhouse gas-neutral high-performance fuels or valuable basic chemical products. As a result of the decentralized approach, customized production and more efficient utilization of the resources available are ensured. The basis is a miniaturized Fischer-Tropsch synthesis in compact microstructured, chemical reactors. The mobile container facilities might be used directly near biogas facilities or gas extraction plants and, hence, increase the value added. At the KIT booth, the Ineratec founders will present the technology.

More information:

http://www.vdi-nachrichten.com/Technik-Finanzen/Edelkraftstoffe-Hightech-Container (in German only)

http://www.ineratec.de/index.php/en/

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.