A research team lead by Professor Martin Wegener at the Karlsruhe Institute of Technology (KIT) has succeeded in realizing a new material class through the manufacturing of a stable crystalline metafluid, a pentamode metamaterial. Using new nanostructuring methods, these materials can now be realized for the first time with any conceivable mechanical properties. The researchers will present their results in the cover story of the May issue of Applied Physics Letters. (DOI 10.1063/1.4709436)

The Rubicon was crossed, so to speak, at the DFG Center for Functional Nanostructures (CFN) and at the Institute of Applied Physics (AP) in Karlsruhe during the past few months. Eventually, numerous three-dimensional transformation acoustics ideas, for example inaudibility cloaks, acoustic prisms or new loudspeaker concepts, could become reality in the near future.

So far, pentamodes, proposed in 1995 by Graeme Milton and Andrej Cherkaev, have been purely theoretical: The mechanical behavior of materials such as gold or water is expressed in terms of compression and shear parameters. Whereas the phenomenon that water, for example, can hardly be compressed in a cylinder is described through the compression parameter, the fact that it can be stirred in all directions using a spoon is expressed through the shear parameters.

The word penta is derived from ancient Greek and means “five”. In the case of water, the five shear parameters equal zero, and only one parameter, compression, differs from that value. In terms of parameters, the ideal state of a pentamode metamaterial corresponds to the state of water, which is why that material is referred to as a metafluid. Theoretically, any conceivable mechanical properties whatsoever can be obtained by varying the relevant parameters.

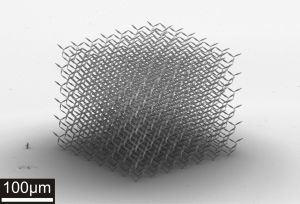

“Realizing a pentamode metamaterial is about as difficult as trying to build a scaffold from pins that must not touch but at their tips,” first author Dr. Muamer Kadic explains. “The Karlsruhe prototype has been manufactured from a polymer. The mechanical behavior of the material is determined by the acuteness and length of the individual “sugar loaves”. On the one hand, we must be capable of designing small sugar loaves in the nanometer range and connect them to one another at the right angle. On the other hand, the entire structure must eventually become as large as possible. Since the material itself contributes only little more than one percent to the respective volume, the composite obtained is extremely light.

“To obtain similar 3D results, as in transformation optics, transformation acoustics is exclusively dependent on metamaterials. In view of this, this first manufacture of our pentamode metamaterial is a quite significant success,” adds Tiemo Bückmann, who is about to receive his diploma at the Institute of Applied Physics and is responsible for realizing the structures of the new material by means of dip-in laser writing, a method that has been derived from direct laser writing developed by the Nanoscribe company.

In recent years, a Professor at the Institute of Applied Physics and CFN coordinator, Martin Wegener and his collaborators, have developed direct laser writing and, based on that method, established optical lithography of three-dimensional nanostructures. Numerous achievements of Wegener’s group in transformation optics e.g., the first three-dimensional cloak of invisibility in the range of visible light have been due to that technique.

About the DFG Center for Functional Nanostructures (CFN)

The DFG Center for Functional Nanostructures (CFN) focuses on an important area of nanotechnology: Functional nanostructures. Excellent interdisciplinary and international research is aimed at representing nanostructures with new technical functions and at making the first step from fundamental research to application. Presently, more than 250 scientists and technicians in Karlsruhe cooperate in more than 80 partial projects coordinated by the CFN. The focus lies on nanophotonics, nanoelectronics, molecular nanostructures, nanobiology, and nanoenergy.

www.cfn.kit.edu

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.