Division I - Biology, Chemistry, and Process Engineering

Division I combines research, teaching and innovation in the scientific disciplines of biology, chemistry and process engineering. Twenty KIT research institutes, the Natural, Artificial and Cognitive Information Processing (NACIP) and Materials Systems Engineering (MSE) programmes in Helmholtz Information and the two KIT Departments of Chemistry and Biosciences and Chemical and Process Engineering form the core of the division.

We focus on our research motif "Material and energy cycles in the circular economy, life science engineering, process technology and digitalisation". In this way, we research and teach the latest processes and methods of material and energy conversion for the circular economy and build a synergistic bridge to the life sciences. In terms of content, the size scales are addressed both theoretically and experimentally from nanogram synthesis to the near-industrial ton scale. All research in Division I is geared to the requirements of a resource-efficient data-based society.

Professor Dr. Andrea Robitzki has been Head of Division I since February 17th, 2020.

Material and Energy Circuits in Circular Economy, Life Science Engineering, Process Technology and Digitization

Researchers at KIT to test the toxic effects of chemical substances using alternative test organisms

Learn moreIm aktuell erschienen Shanghai Global Ranking of Academic Subjects (GRAS) 2025 belegen die Kernfächer des Bereich I wieder Spitzenpositionen.

Mehr

Discovery of smOOPs sheds light on why certain RNAs cluster into condensates – a breakthrough that opens new avenues for disease research

Learn more

Boris Karanov and Frank Rhein receive funding from the Carl Zeiss Foundation – the “CZS Nexus” program promotes interdisciplinary research ideas in STEM disciplines

Learn more

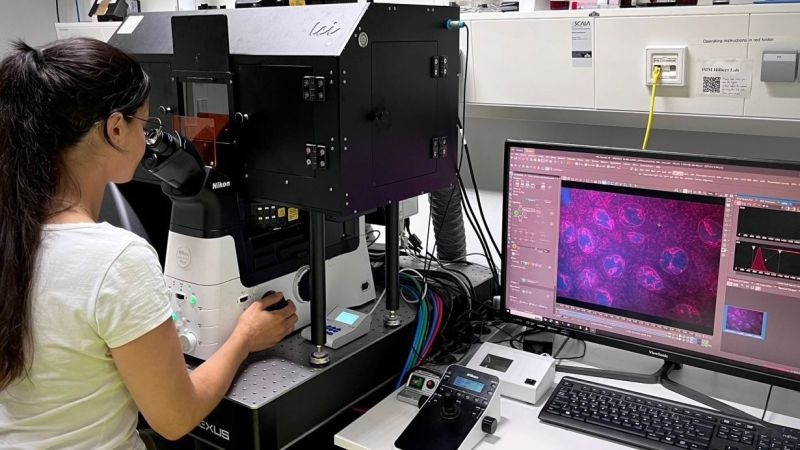

Stem cells process genetic information as quickly as computers – Cellular Information processing as inspiration for biotechnology

Learn more

KIT researchers investigate the function of CPD photolyase in blind cave fish

Learn more

KIT researchers have uncovered how a bacterium actively switches off its disease-causing mechanisms at high cell density and evades the immune system — a possible key to better fighting infections

Learn more

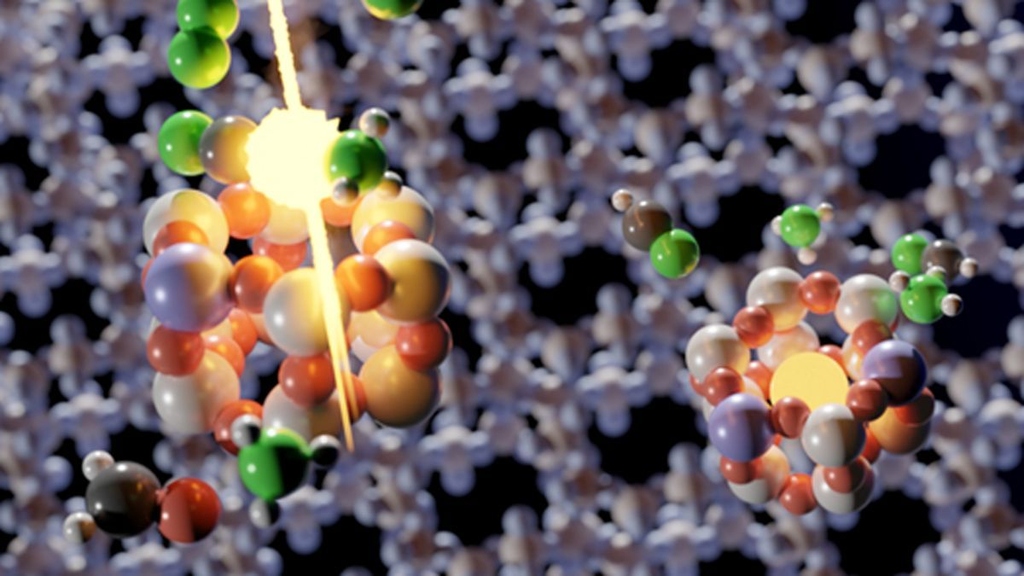

KIT researchers are improving catalysts to reduce the formation of toxic by-products when using synthetic fuels

Learn more

The CIW Women Engineers Network (CIW IN) was founded in 2021 by the KIT Department of Chemical and Process Engineering (CIW) as part of the ExU Gender Equity 1 project. The aim is to enable both professional and social exchange for women within the department, regardless of where they are in their scientific careers.

link