Global population is increasing, crucial resources become scarcer. Producing enterprises today have to take the right steps for a sustainable future. On their behalf, scientists of Karlsruhe Institute of Technology (KIT) study how the production process may be improved by autonomous production control, reduction of wear parts, or principles of resource-efficient production. Their know-how is presently being pooled in the new research focus “Sustainable Production.”

The new research focus “Sustainable Production” of the wbk Institute of Production Science is to push transition of production processes from linear to circular economy. This also includes remanufacturing, i.e. the reprocessing of spent products at modular plants for disassembly and reassembly, autonomous production control, and integrated quality assurance as well as production networks and business models needed for circular economy.

DigiPrime: Information Flow in Circular Economy

One of presently 15 research projects in this area is “Digi-Prime - Digital Platform for Data-enhanced Circular Economy Business Models.” DigiPrime is aimed at developing a digital platform for in-formation flow between various actors in circular economy and at ensuring that no information is lost along the chain of added value. In particular, life cycle data, such as utilization statistics and frequent error causes, will be used to improve internal planning of reprocessing in this complex and dynamic environment. By integrating industrial and social clusters, the project team wishes to reduce barriers in product processing, sales, and use in the second life cycle. In pilot projects, new concepts are developed, tested, and prepared for commercialization. The European Commission funds the project with about EUR 15 million for a duration of four years.

Research Focus on Challenges and Goals of Industry

“A new research focus of wbk does not only result from theoretical considerations, but in close exchange with partners from industry. Together, we identify future challenges and goals. In this way, our solutions can be implemented directly in industry,” says Professor Gisela Lanza, Head of KIT’s Institute of Production Science (wbk). A research focus is of high economic, social, and technical relevance and comprises several research. A research focus of wbk implies that work is performed from various perspectives. It may exist for sometimes 15 years and, hence, extend far beyond the duration of most research projects. Within the new research focus, scientists want to make the processes, plants, systems, and networks more sustainable and, in this way, enhance resource efficiency.

Political relevance is reflected not only by climate neutrality that is to be reached in Germany by 2050, but also by the circular economy strategy of the European Union. Among others, this strategy is aimed at developing sustainable processes and products that are long-lived or can be reused, repaired, or reprocessed. Moreover, the demand for new resources is to be reduced.

First Steps towards Sustainable Production

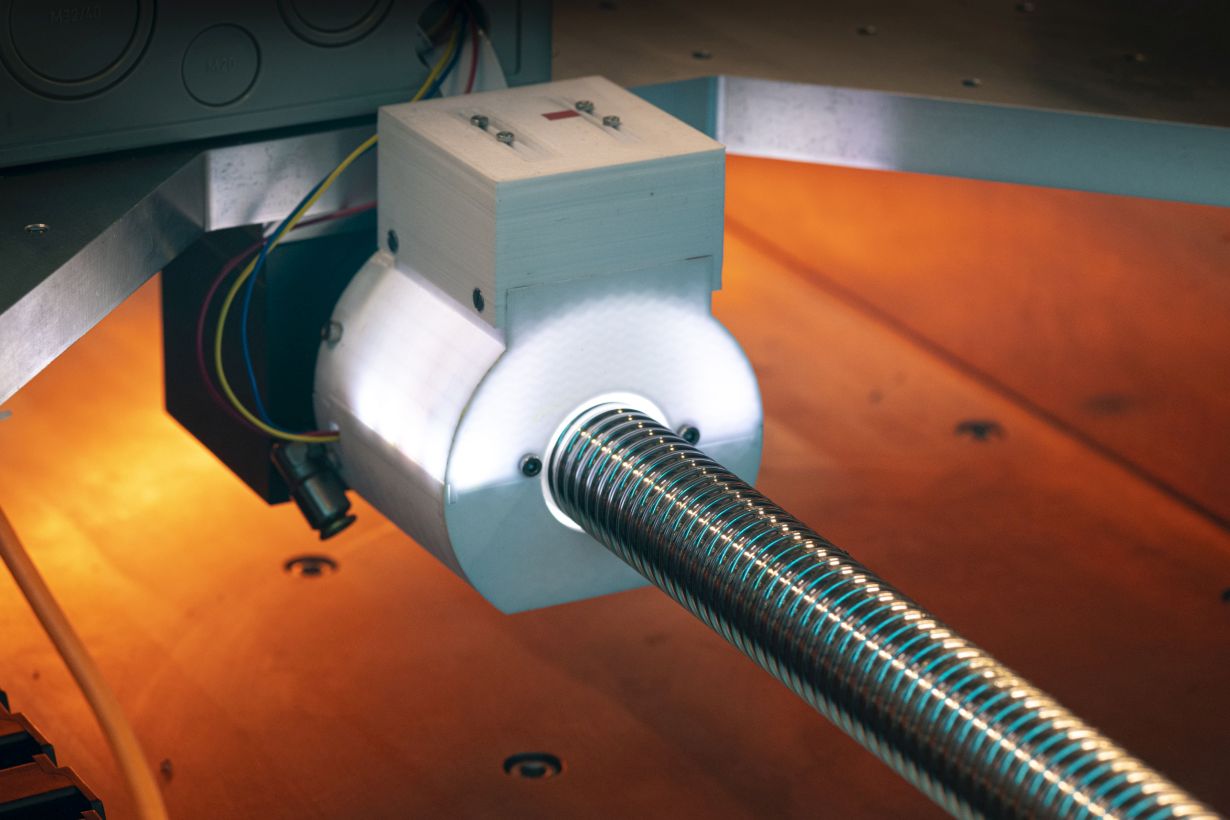

Companies that will continue to work in linear production chains will also be supported by researchers in enhancing resource efficiency. For this purpose, resource-efficient components are developed and the corresponding plants are designed. Moreover, material and energy efficiency of production processes are improved. A research project on anticipatory repairs is aimed at enhancing resource efficiency of screws, nuts, and the corresponding components. The “Acoustic Emission Sensors“ project focuses on ball screw drives and the question of how these components can be operated as long as possible without any risk. Presently, ball screw drives are exchanged very early on a preventative base, as they are associated with the risk of failing and causing outage of a machine tool and of entire production in the worst case. Acoustic emission sensors, i.e. sensors that measure events in the low-frequency ultrasonic range between 20 kHz and 2 MHz, detect early signals of an imminent failure of the ball screw drive. Such sensors allow to monitor the ball screw drive and to exchange it at an ideal point of time, thus reduc-ing their consumption. The project is funded with about EUR 266,000 by the German Research Foundation (DFG).

Resource Efficiency Thanks to Optimized Processes

Another method to make manufacture more resource-efficient and respond to disturbance variables in the process is surface conditioning. This priority program scheduled for a duration of six years is funded by the DFG with EUR 12 million. Within the project, processes to optimize component edge layers are studied. The goal is to design dynamic forward controls by combining adequate sensors with simulation calculations and artificial intelligence. In this way, the manufactured components will reach the desired state in the pro-cess in spite of existing disturbances. Service life of the products is increased, material consumption is reduced, and energy efficiency of assemblies is improved decisively.

More information: https://www.wbk.kit.edu/english/index.php

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.