A software that overcomes language barriers with artificial intelligence, sensors that identify odors, and a power-to-gas process with an efficiency of more than 75%: These are only some of the topics presented by Karlsruhe Institute of Technology (KIT) at Hannover Messe 2019 “Integrated Industry – Industrial Intelligence.” From April 1 to 5, 2019, KIT will present its innovations at two trade shows: “Research & Technology” (Hall 2, stand B16) and “Integrated Energy” (Hall 27, stand L51).

“Innovations for the transformation of our energy system or smart technologies for digital and networked production in globalized economy: At Hanover, we will present sustainable solutions to master the challenges of our time. The far-reaching change of our work environment results in opportunities to shape the future,” says the President of KIT, Professor Holger Hanselka. “We want to contribute to this change for the benefit of our society and industry. At two stands in the research and energy halls, we will present showcases full of technologies and smart processes that provide a view into the future.

Information on the stands and exhibits of KIT at Hannover Messe 2019 can also be found in our digital press kit: http://www.sek.kit.edu/english/4330.php

KIT in Hall 2, B16 –”Research and Technology“

Artificial Intelligence: Breaking the Language Barrier

International exchange in business or politics requires human interpreters. But requirements and fees are high. Interpreters cannot be hired for all purposes. Researchers of the Interactive Systems Lab of KIT will present a self-learning system for automatic simultaneous translation. It combines automatic speech recognition with machine translation and other auxiliary functions. The result is made available on a website that allows for later search via text queries. The speech recognition part can also be used to provide real-time transcripts of speeches. The concept was proved by a test at the European Parliament. Software-based efficient and transparent communication also has major advantages in many business sectors. The system is in a mature stage. In 2012, the automatic lecture translator was installed in lecture halls of KIT and since then, has helped international students follow lectures given in the German language.

Sensor Technology: The eNose Digitally Analyzes Odors

The odor analysis market has offered isolated and very expensive solutions for specialized applications so far. The focus is on precise chemical analysis of gas components rather than on easy use. This situation will now be changed: Together with the industry partner smelldect, KIT develops an electronic nose, the eNose, that is able to rapidly and easily acquire important olfactory information. It can determine whether an odor corresponds to a previously learned reference odor and, hence, has to be classified hazardous or harmless. The artificial nose has a size of a few centimeters only and consists of a chip with nanowires made of tin dioxide. After a certain odor pattern has been taught to the chip, the odor sensor can identify it within seconds. The eNose is to be inexpensive, capable of learning, and, hence, universally usable. Potential applications range from smart fire detectors to room air monitoring or food control. At Hannover Messe, KIT and smelldect will present a ready-for-use eNose demonstrator. In future, the sensor is planned to be miniaturized for integration into smartphones.

Sommer, KIT)

Smart Materials: Bionic Ship Coating Reduces Friction Losses

Thanks to the salvinia effect, certain plants, such as water ferns (salvinia), can breathe under water. They retain a thin air layer on the surfaces of their leaves that are covered with hair-like structures and are highly water-repellent. This strategy of nature is the model of a ship coating developed within the EU-funded AIRCOAT project that started in 2018. Ten research institutions are involved in the project that is coordinated by KIT. At Hannover Messe, scientists of AIRCOAT will present the demonstrator of an adhesive foil that is applied onto the ship’s hull. The foil produces a thin air layer that significantly reduces drag and acts as a physical barrier between the hull’s surface and water. As a result, fuel consumption and exhaust emission of the ship can be reduced considerably. The air layer also reduces the emission of noise. Moreover, it prevents marine organisms from settling on the hull, so-called fouling, and the release of biocidal substances from the coatings below into water.

Industry 4.0: One Click to Produce a Digital Twin

Digitization is associated with a number of possibilities for companies to optimize existing processes or enter completely new paths. Production of a digital twin, a 3D copy of reality, enables innovative solutions along the lifecycle of buildings, manufacturing processes, and products. Today, digital twins no longer are of interest to large companies only. Also medium-sized enterprises can save costs and time, while flexibility is enhanced. KIT will present a system developed by the Industry 4.0 Collaboration Lab. This system uses a central service to supply all 3D inventory data needed for a digital twin independently of the hardware and software. Automatic generation of 3D models from point clouds using the “Click & Build” technology is of crucial importance. New algorithms enable users to transfer the data measured by a drone, for instance, to virtual 3D objects by just one click.

Preservation of Infrastructure: KIT Innovation HUB Improves Prevention in Construction

Preserving roads and bridges or ensuring stable water and energy supply is an expensive and complex task. To preserve infrastructure facilities, however, also new challenges, such as global warming or scarcity of natural resources, have to be mastered. More and more frequently, infrastructure facilities fail far before the expiry of their planned service life. With a unique approach the KIT Innovation HUB develops preventive measures in the form of innovative products, technologies, and services. All stakeholders in the construction value change are integrated, from the raw materials manufacturers to the builder. Using the “nano-to-macro approach,” detailed knowledge on the behavior of construction chemicals on the molecular level is obtained. In the next step, marketable products, technologies, and services are designed in cooperation with partners from industry and science. This strategy has already been implemented successfully on the aviation areas of Leipzig airport and the Laufenmühle viaduct near Welzheim.

Technology Market

RESEARCH TO BUSINESS, KIT’s technology market, will present 90 further technology offers at the stand of KIT. These are innovations of KIT, which might be turned into marketable products and processes.

KIT in Hall 27, Stand L51 – “Integrated Energy”

Energy Storage Systems: Integrated Solution for a Flexible Power Grid

Due to the increasing proportion of renewable energies in the power grid, energy storage systems are gaining importance to ensure stable power supply. Today’s use of battery storage systems is associated with high costs. Apart from investment costs, operation costs also play an important role. At the Energy Lab 2.0, a large-scale energy research facility at KIT, a close-to-production prototype of a large lithium-ion storage system with very low operation and maintenance costs is now being implemented. The efficient control system required for this purpose was developed by KIT’s Battery Technical Center. In addition, cooling of the prototype was optimized. Besides cooling water from geothermal probes, a concrete shell is used for passive cooling. Proper cooling increases the service life of batteries and, hence, economic efficiency. The new storage system supplies 1.5 MWh of usable energy and can reach an electric power of up to 800 kW. Optimal operation is ensured by two independent battery and inverter systems. They enable continuous operation of the storage system even if one of the components fails. As part of the building is located underground, the space needed for the battery storage system is reduced. An attractive design enhances acceptance by local population when used within urban spaces.

Power Transport: Energy-efficient Superconducting Cable for Future Technologies

For connection of wind parks, DC power supply on ships, or high-current cables in future electric airplanes, scientists of KIT will present a multi-purpose superconducting cable for loss-free power transport, which can be manufactured easily, the HTS cross conductor (HTS CroCo for short). It is based on REBCO material (rare-earth barium copper oxide), a high-temperature superconductor (HTS) discovered in 1987. While superconductors usually work at temperatures near -269°C only, the REBCO material can be applied at a temperature of -196°C already. Yet, long lengths are available in the form of thin tapes only. Physicists of KIT have now developed a method to produce high-current cables from these HTS REBCO tapes. The HTS CroCo consists of REBCO tapes of two different widths, which are arranged with a cross-shaped cross section. HTS CroCos can transport very high direct currents and compared to conventional copper or aluminum cables, they need less space and have a lower weight. If liquid hydrogen is used for cooling, it is even possible to transport chemical energy and electrical energy together. The biggest advantage, however, consists in loss-free energy transport by the superconductor and the associated environmentally compatible and energy-efficient solutions.

Video: Energy-efficient superconductors for future technologies https://youtu.be/HwpILNMpojE (in German)

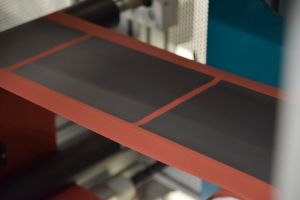

Production Technology: Reducing Costs of Battery Cell Production

Electrode foils play a decisive role in the production of batteries and accumulators for electric cars, smartphones, and laptops. The electrode material is applied as a thin paste to a copper or aluminum foil, with the electrode patterns being separated by small strips of uncoated foil serving as electrode conductors. To produce these uncoated areas, the coating process has to be stopped and restarted again. This takes a lot of time and increases production costs. Researchers at KIT are now able to significantly increase production speed with a new intermittent, i.e. interrupting, process. They use a patented nozzle equipped with a special membrane which is able to interrupt the coating process abruptly and to restart it again. As no other moving parts are required, production speed can be increased. Instead of the 25 to 35 meters previously common in the industrial sector, more than 100 meters per minute of coated film for battery electrodes can now be produced.

Power-to-Gas: Production with High Efficiency

Solutions for the storage of regenerative energies are of decisive imp ortance in implementing the energy transition. Generation of synthetic natural gas (SNG) from renewable energies enables power storage in the existing natural gas grid and use of SNG without fossil CO2 emissions. Usually, hydrogen is produced by low-temperature electrolysis. This hydrogen is then converted into SNG in a methanation plant. The EU-funded project HELMETH (Integrated High-Temperature ELectrolysis and METHanation for Effective Power to Gas Conversion) coordinated by KIT has now shown that efficiency in the production of SNG from electric power can be increased by combining both processes. Consistent use of synergies from high-temperature electrolysis and methanation in the HELMETH prototype resulted in efficiencies of power-to-SNG conversion of 76%. This is much higher than the usual 54% of existing power-to-SNG facilities. Larger industrial plants might even reach efficiencies over 80% in case of further optimization. On April 01, 2019, Dr. Stefan Harth will speak about the highly efficient power-to-gas process at the Integrated Energy Forum from 16.30 to 17.00 hrs (Hall 27, stand L55).

Technology Market

RESEARCH TO BUSINESS, KIT’s technology market, will present 30 further technology offers at KIT’s Energy stand. These are innovations of KIT, which might be turned into marketable products and processes.

The Kopernikus Projects at Hannover Messe

The Kopernikus projects ENSURE, SynErgie, P2X, and ENavi will be presented at the stand of the Federal Ministry of Education and Research (Hall 2, stand B22). Visitors may have a look at the future energy landscape. In addition, a series of lectures will be given at the Integrated Energy Forum on Monday, April 01, 2019 from 15.30 to 16.30 hrs (Hall 27). They will focus, among others, on digital power supply grids, a topic covered by the KIT-coordinated Kopernikus project ENSURE.

KIT and Its Partners at Other Thematic Stands and in the Conference Program

BIOKON Joint Stand A01 in Hall 2: The Body Language of Components

At the BIOKON joint stand, KIT, based on exhibits and the books by Professor Claus Mattheck, will present innovative lightweight construction and component optimization methods derived from natural structures.

Network Park in Hall 13, Stand E21: Spinoff and Startup Teams of KIT Present Themselves

Experience innovation: At the Young Tech Enterprises Network Park, KIT will introduce its startups and spinoffs heat_it, HQS Quantum Simulations, thingsTHINKING, axxelera, Selfbits, promonode, and SIMUTENCE. Please refer to http://www.kit-gruendernews.de/hmi-2019/ (in German) for more information and for the detailed plan of exhibitors.

FZI Stand C47 in Hall 2: Process Optimization by Artificial Intelligence (AI)

The FZI Research Center for Information Technology, an innovation partner of KIT, will present the AI-based self-learning walking robot LAURON and an intelligent Internet-of-things solution for logistics and production. Moreover, it introduces its research into automated electric minibuses on the autonomous driving test field Baden-Württemberg. The Competence Center for IT Security of FZI sensitizes users to IT security as a cross-cutting issue in all areas of life. Please refer to https://www.fzi.de/aktuelles/termine/das-fzi-auf-der-hmi/ (in German) for more information.

Forum Integrated Energy, Hall 27, Stand L55: Visions of Future Mobility

On April 03, 2019 from 12.45 to 13.15 hrs, Professor Albert Albers, Head of KIT’s Institute of Product Engineering, IPEK, will speak about “Seamless Mobility” as a system of systems. Based on this new approach, he will present methods and ideas for the systematic integrated development and assessment of reasonable and viable mobility solutions.

Forum Integrated Energy, Hall 27, Stand L55: Electrochemical Energy Storage Systems of the Future

On April 03, 2019 from 17.00 to 17.30 hrs, Professor Maximilian Fichtner, Spokesperson of CELEST, will present the activities of this new Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST), one of the biggest and most ambitious research and development platforms in this area worldwide.

Forum Integrated Energy Hall 27, Stand L55: Power-to-SNG with High Efficiencies

On April 01, 2019, from 16.30 to 17.00 hrs, Dr. Stefan Harth will present the highly efficient power-to-gas process developed within the EU-funded and KIT-coordinated project HELMETH (Integrated High-Temperature ELectrolysis and METHanation for Effective Power to Gas Conversion).

Integrated Lightweight Plaza & Speakers’ Corner, Hall 5, Stand B18: Process Modeling of Filament Winding as a Joining Process

On April 01, 2019, Marius Dackweiler will present a novel joining process for fiber composites from 14.30 to 15.00 hrs. By means of a C-shaped rotor-stator construction and an articulated robot, filament nodes are generated.

Artificial Intelligence – Topic of the lookKIT Research Magazine

It is a ubiquitous term, it will change our lives and daily routines, our work, and our society: Artificial intelligence (AI). But how can AI be used in future for helping people and generating added value for science and industry? Researchers of KIT analyze this question from various perspectives. Their activities as well as opportunities and risks of AI are covered by the latest lookKIT magazine. In an interview, the President of KIT, Professor Holger Hanselka, reports his work in the Steering Committee of the Learning Systems Platform of the Federal Ministry of Education and Research. Other issues covered are robotics, autonomous driving, and successful AI-related startups of KIT: https://www.sek.kit.edu/english/3216_4301.php.

Information on the stands and exhibits of KIT at Hannover Messe 2019 can also be found in our digital press kit: http://www.sek.kit.edu/english/4330.php

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.