Gaining practical experience online – this sounds contradictory, but will be possible soon at Karlsruhe Institute of Technology (KIT). At the education and research institution, the first robotics learning laboratory of its kind will be established. Apart from students and researchers of KIT, thousands of online users from all over the world will be given access. On the Udacity education platform, they will have the opportunity to control the robots made by high-tech manufacturer KUKA via a web interface and to test their programs and algorithms developed. In this way, KIT will enable robotics students to work on real industrial and scientific problems. In return, the researchers hope to get the crowd’s support in solving these problems.

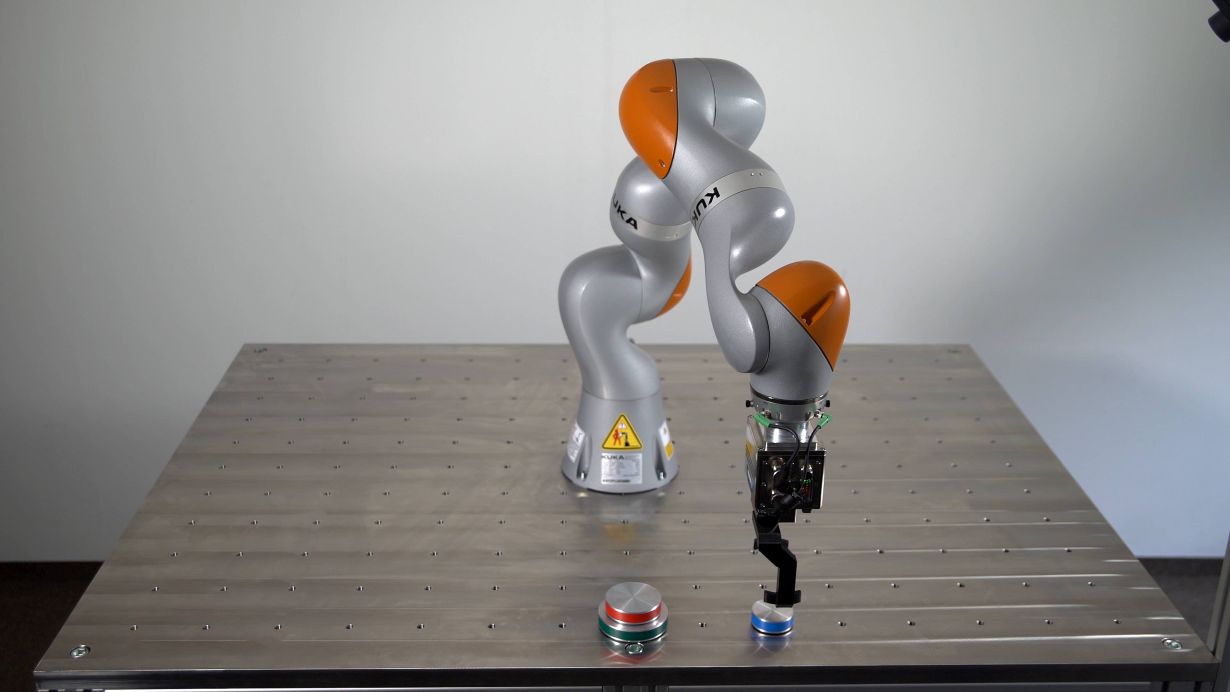

“Our robots will run seven days a week, 24 hours a day. This is a vast potential for crowd experiments,” says Torsten Kröger, Head of KIT’s Institute of Anthropomatics and Robotics, where the KUKA Udacity Robot Learning Lab will be established. He is responsible for intelligent process automation and robotics. At the Robot Learning Lab, students in Karlsruhe and those logging in via the internet are given access to KUKA’s lightweight robot arms with grippers for testing. By the end of this year, the number of robots will further increase. The robot arms can be activated online. In a livestream, students can then observe via cameras how the industry robots follow their commands.

“The lightweight robots are equipped with sensors at the joints that detect the acting forces and, hence, also collisions. The robot is suited for delicate assembly applications on smallest space together with a human being without a safety fence being needed,” says Rainer Bischoff, Head of KUKA Corporate Research. “The KUKA robots are predestined for education of students on site and online. The Robot Learning Lab will raise education and research in robotics and AI to a higher level.”

The robots will be used in the basic education of students, but also for real applications, such as autonomous gripping, placing of objects, and execution of assembly tasks. In the area of research, the robots are planned to independently learn certain tasks, without any programming.”

“With the lab in Karlsruhe, we extend our scope of offers in the area of robotics by a direct practice-relating application that can be used all over the world,” says Christian Plagemann, VP Learning of Udacity. Up to 7500 future software developers and roboticists will be able to test their self-developed technical solutions and programs at the Learning Lab every year. This will give rise to a large volume of data that can be used by KIT’s scientists for research projects.

“Considering the large number of skilled and motivated talents using the laboratory, it is very reasonable to study complex scientific and technical issues there,” Kröger says. When a group of 2000 students, for instance, is given a very difficult problem to work on, probability of finding a very smart solution yielding a scientific, innovative or technical added value is very high.

More about the KIT Information · Systems · Technologies Center: http://www.kcist.kit.edu

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.