A smart platform for the energy transition, innovative technologies for electric mobility and photovoltaics as well as a revolutionary process for the production of glass: These are only some of the activities presented by Karlsruhe Institute of Technology (KIT) at Hannover Messe 2017. From April 24 to 28, KIT will present its projects at two of the leading trade fairs: For the first time, at the “Energy” trade fair (hall 27, stand H51) and as in the past years at the “Research & Technology” trade fair (hall 2, stand B16).

“The Energiewende is not only a big challenge for our energy system, it also offers enormous opportunities for society, industry, and the environment. The corresponding innovative technologies can only be developed in close cooperation between science and industry,” says the President of KIT, Professor Holger Hanselka. “This also holds for new technologies for electric mobility, lightweight construction, or materials sciences. For this reason, we further increased our traditionally strong commitment at Hannover Messe. Apart from the stand at the “Research & Technology” leading trade fair and other theme stands, we will also have a stand at the “Energy” leading trade fair this year.”

On the first day, April 24, from 3.40 p.m., Federal Minister of Research Johanna Wanka will visit the stand of KIT at the “Energy” leading trade fair in hall 27 (stand H51) to inform herself about KIT’s energy research activities. Among others, KIT will present the KIT-coordinated ENSURE consortium, one of four Kopernikus projects for the energy transition funded by the Federal Government. ENSURE is aimed at developing and testing efficient, viable grid structures which are characterized by the interaction of both centralized and decentralized energy supply. “ENSURE will decisively contribute to the economic success of the energy transition and to technology suppliers, infrastructure operators, and electricity consumers profiting from it,” Hanselka says.

Information on the stand and exhibits of KIT at Hannover Messe 2017 can also be found in our digital press kit: www.sek.kit.edu/hannovermesse2017

KIT in Hall 27, Stand H51 – “Energy”

Energy Lab 2.0 – Smart Test Platform for the Energy Transition

The Energy Lab 2.0 is the first system of its kind that smartly interconnects electricity producers, storage systems, and consumers. The grid consisting of plants at various locations links electric, thermal, and chemical energy flows as well as latest information and communication technologies and serves as a test grid, in which KIT scientists and their partners study the interaction of centralized and decentralized energy supply. Realization of the energy transition requires adequate and reliable storage technologies, smart grid extension, and maintenance of grid stability. The Energy Lab 2.0 pushes the Energiewende and in particular integration of renewable energy sources. Project partners are the German Aerospace Center (DLR) and Forschungszentrum Jülich (FZJ), which also are members of the Helmholtz Association.

The Energy Lab 2.0 interconnects electricity producers, storage systems, and consumers. (Photo: KIT)

INERATEC®: High-quality Fuel from the Minireactor

Small natural gas resources and gases in thousands of oil fields, whose oil production was stopped, presently remain unused. INERATEC®, a spinoff of KIT, has developed a marketable, compact chemical facility that converts methane-containing gases of such wells or gases arising from residues of oil production or biogas production into synthetic liquid fuel. Moreover, the plant can convert regenerative hydrogen and the greenhouse gas carbon dioxide into fuels. The main element of the new technology is a microstructured chemical reactor developed by researchers of KIT.

The microstructured chemical reactor can convert methane-containing gases into liquid synthetic fuels of highest quality. (Photo: INERATEC/KIT)

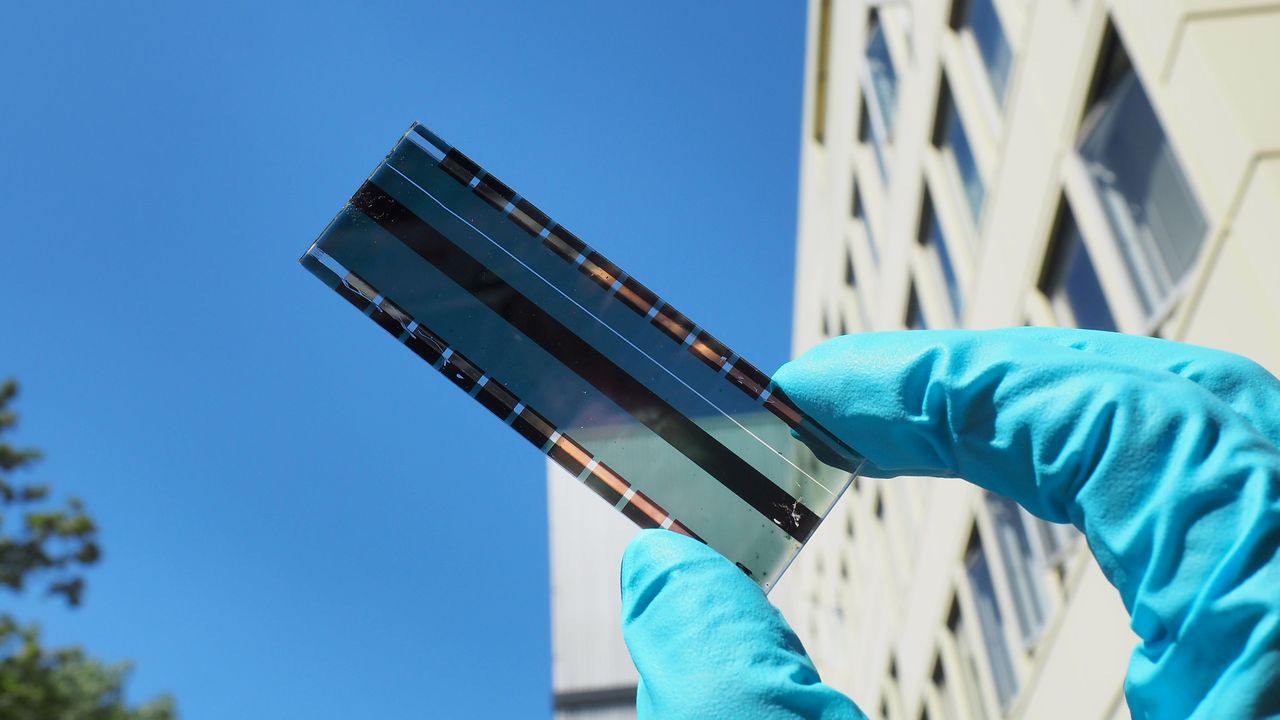

Solar Cells: The Flexible Generation

Organic solar foils might revolutionize energy production, because they have a number of advantages over conventional silicon solar cells. They have a small weight, are mechanically flexible, transparent, and can be produced in a large range of colors. This allows for use in new areas of application – examples being solar windows in buildings or sunglasses. Researchers of KIT will present these applications at Hannover Messe. Together with MJR PharmJet GmbH, they have developed a process for coating and printing organic solar cells that is environmentally compatible, while material and energy consumption and costs are reduced. For the production of this new type of organic solar cells, no hazardous solvents are required. Their efficiency corresponds to that of conventional organic solar cells.

Solar glasses with lenses made of semi-transparent organic solar cells. (Photo: Alexander Colsmann, KIT)

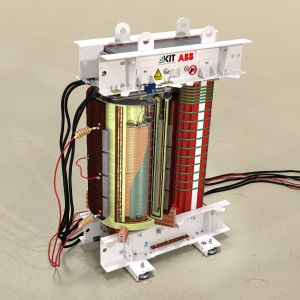

2 in 1: The Superconducting Transformer

A single device that is both a transformer and a current limiter: This is achieved by combining a normal conducting primary coil with a superconducting secondary coil. Scientists of KIT will present the prototype of a 2-in-1 transformer. When used at transformer stations, it will also protect the other grid components in case of fault currents.

The 2-in-1 transformer combines a normal conducting primary coil with a superconducting secondary coil (Photo: Sebastian Hellmann, KIT)

Technology Market

RESEARCH TO BUSINESS, the technology market of KIT, will present 30 additional technology offerings at KIT’s Energy stand. These offerings are innovations made by KIT. Now, cooperation partners are needed for their commercialization.

KIT in Hall 2, B16 – “Research and Technology”

Liquid Glass – A Revolution in Glass Processing

Glass is one of the most important and fascinating materials mankind has ever used. It is highly transparent and highly resistant to heat and acids. It is omnipresent in everyday life. Its outstanding optical, chemical, and thermal properties make glass an attractive material for extremely small components, such as minute optical lenses or complex microsystems, e.g. laboratories on chips for the analysis of smallest liquid volumes. So far, high temperatures and the use of hazardous chemicals were required to produce such microstructures. Scientists of KIT have now developed a simple alternative: “Liquid Glass” is viscous at room temperature and can be shaped into any form, pre- cured under light, and baked out in the furnace. Hence, structuring glass components is (nearly) as easy as baking cookies. The initial material used for the process is a nanocomposite, a mixture of pulverized glass and plastic, that can be processed like a plastic material.

Video on “Liquid Glass:” www.sek.kit.edu/liquidglass.php

(Quelle: NeptunLab)

“Liquid Glass“ is viscous at room temperature and can be shaped into any form. (Photo: NeptunLab)

“Liquid Glass“, the simple replication of glass, is now possible. (Photo: NeptunLab)

e²-Lenk: Steering Force in the Drive Train

In conventional vehicles, the combustion engine does not only accelerate the car, but also supplies onboard auxiliary systems with energy, for e.g. assisted steering. In electric vehicles, this energy comes from the battery, while range is reduced. A novel concept for an intelligent assisted steering system with optimal energy efficiency for electric vehicles has now been developed by researchers of KIT and Schaeffler AG. The assisted steering function is integrated into the drive train by using an intelligent control concept for the drive torques of the individual wheels and a suitable chassis geometry. A conventional assisted steering system is no longer required. In this way, weight, energy consumption, and costs are reduced, while the range is increased.

ELF++ demonstrator vehicle for the evaluation of an assisted steering system by wheel-selective drives. (Photo: e²-Lenk project team)

Thread Whirling: Increasing Efficiency through Synchronous Turning

Whirling is an attractive method for producing threads of high surface quality for e.g. medical bone screws. By means of this method, precise profiles can be milled. However, productivity is limited by the necessary preceding process of turning the outer contour. Synchronized whirling is a high-performance type of the method for simultaneous turning and whirling of the component. In addition, the new process opens up potential for optimization. Engineers of KIT study the performance of this new method in a research and development project in cooperation with the companies of Index, Paul Horn, and smith&nephew.

The new process allows for simultaneous turning and whirling of components. (Photo: Markus Breig, KIT)

Light and Effective: Power Electronics Components for Electric Mobility

Researchers of KIT will present electric motors and power electronics components for the drive train of electric vehicles. Battery management systems, power electronics modules, inverters, and electric motors developed for electric mobility have a smaller weight, need less installation space, and achieve higher efficiency. They are based on silicon carbide power semiconductors and magnetic materials of customized geometries. By means of new winding and cooling technologies developed after several years of research, electric motors were improved considerably. KIT will present a machine with a permanent power density of more than 8 kW/kg. It is applied in the Formula Student, where it made the KA-RaceIng team reach the first place in the international “Formula Student Electric 2016.”

Rotors of a high-speed synchronous motor of 30,000 r.p.m. excited by a permanent magnet. (Photo: Simon Mangels, KA-RaceIng)

Unique Luminescent Characteristics: Photonic Markers

At first glance, anti-counterfeiting and error-free high-throughput sorting of plastics do not appear to have much in common. But placing of a unique fluorescent label within the product - whether this is a pair of designer sunglasses or a plastic milk bottle - combined with the ability to detect this unique label again may play an important role in both processes. Nanophotonics experts of KIT, in cooperation with Polysecure GmbH, develop various types of such photonic markers with unique luminescent properties, minimum environmental risk, and excellent stability.

Photonic markers exhibit emissions under infrared light excitation. (Photo: Irina Westermann, KIT)

Technology Market

RESEARCH TO BUSINESS, KIT’s technology market, presents another 90 technology offerings at this stand of KIT.

KIT at the Baden-Württemberg Pavilion, Hall 27, H71:

Selected research institutions in Baden-Württemberg – Karlsruhe Institute of Technology (KIT), Ulm University, the University of Stuttgart, and the Aalen and Esslingen Universities of Applied Sciences – have joined the XiL-BW-e Network of Laboratories for Electric Mobility, the first network of research facilities and laboratories of this kind. Expertise and testing infrastructures for electric mobility are pooled by a holistic approach for scientists to use them at other locations as well. Apart from an interconnection of test rigs, interfaces exist to the battery analysis network. Among others, it is possible to study drive train components in interaction with novel batteries under real conditions. The Network of Laboratories can be extended as needed and is also available for use by industry partners. More information: www.xil-bw-e.de (in German only).

The Baden-Württemberg Test Area for Automated Driving is being established in Karlsruhe under participation of KIT for companies and research institutions to test future-oriented technologies and services for networked and autonomous driving in daily road traffic. The test field pools the activities of partners in research and application as well as of automotive and information and communication technologies industries. More information: http://www.kit.edu/kit/english/pi_2016_105_karlsruhe-to-pioneer-autonomous-driving.php

The alliance “Karlsruhe Priority Region for Mobility Systems” pools the competences of research institutions in Karlsruhe and several industry partners in the area of mobility systems. Among others, OPTICAR will be presented, a test vehicle for fully automated and driver-less driving, where the focus lies on the further development of optical perception of the environment. For this, the vehicle is equipped with twelve stereo cameras all around. They may also be coupled virtually to new stereo cameras. This enables precise all-around perception of objects and movements even at larger distances. More information: www.profilregion-ka.de (in German only).

KIT at Other Stands:

- Hall 2, A01 – BIOKON joint stand: Lightweight construction and optimization of technical components modeled on nature

- Hall 3 – daily presentation of various startups of KIT at the Young Tech Enterprises Network Park

- Hall 2, C40 – TU9/VDI

Industry 4.0 – in the Podcast and Magazine of KIT

For the KIT.audio research podcast on Industry 4.0, author Michael Lissek met experts of KIT working in the areas of computer science, production engineering, technology transfer, and technology assessment. They all work on realizing the Industry 4.0 vision and think about [KIT.audio | Der Forschungspodcast des Karlsruher Instituts für Technologie (Grafik: Ken Pekarsky, KIT)] the impacts on society. Listen to our podcast at www.kit.edu/audio (in German only).

Parallel to the Hannover Messe, the latest issue of KIT’s research magazine “lookKIT” will be published. It contains a number of contributions on “Industry 4.0:” Among the topics covered are a graphics tool to illustrate data flows and to identify, combine, and represent a company’s process flows, Industry 4.0 guidelines, as well as the ScaleIT project focusing on hardware and freely configurable software for medium-sized enterprises. Click www.sek.kit.edu/kit_magazin

For information on the stands and exhibits of KIT at 2017 Hannover Messe, click our digital press kit: www.sek.kit.edu/hannovermesse2017

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.