At the 2016 Hannover Messe from April 25 – 29, Karlsruhe Institute of Technology (KIT) will present innovative technologies for future energy supply, lighting, and lightweight construction (hall 2, B16). By means of a production concept developed by KIT, battery packs for stationary storage systems can be produced safely, flexibly, and at low cost. KIT has also developed a sustainable method for the production of novel organic solar cells: The coating process does not require any substances hazardous to health or the environment. In addition, KIT will present luminescent coatings for three-dimensional components, a process for preforming textile materials in lightweight construction, and a 3D printing technology for high-performance polymers.

“The big projects of our society, such as energy transition or future mobility, will only succeed, if science and industry exchange knowledge and cooperate closely. Our clear objectives are innovative technologies that are sustainable and affordable at the same time. I am very happy that we will present such processes at this year’s Hannover Messe. They were developed by researchers of KIT together with industry partners or by our spinoffs,” the President of KIT, Professor Holger Hanselka, says.

Video einbetten:

<iframe width="560" height="315" src="https://www.youtube.com/embed/aFbN78Rgoz4" frameborder="0" allowfullscreen></iframe>

Stationary Storage Systems: Battery Pack Assembly

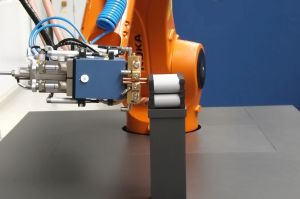

Stationary storage systems are crucial to future energy systems with high shares of fluctuating renewable energy sources, such as solar and wind power. Development of reliable, highly efficient, and inexpensive storage systems is necessary for the success of the energiewende and a central activity of KIT. In this connection, KIT scientists have developed an innovative manufacturing and assembly concept for modular, scalable battery packs. “The automated robot production line ensures reliable and efficient welding of battery cells. Our focus lies on consistently high process quality and on production speed and flexibility,” Dr. Olaf Wollersheim of KIT’s Competence E Project explains. With an overall welding time per battery pack of eight spherical cells of less than one minute, the optimized assembly process also is economically interesting. The battery packs can then be interconnected to battery systems of high storage capacity.

Renewable Energy Sources: Environmentally Friendly Solar Cells

Organic solar cells can open up entirely new markets for photovoltaics, because these “plastic solar cells” have many advantages over conventional inorganic cells: “They are light, mechanically flexible, and can be produced in many colors. Thus, they open up a variety of applications,” Dr. Alexander Colsmann of KIT’s Light Technology Institute explains. So far, precipitation of layers of light-absorbing organic semiconductors has required the use of solvents harmful to health. KIT researchers, in cooperation with MJR PharmJet GmbH, have now developed an environmentally compatible process for the coating and printing of organic semiconductors, by means of which consumption of materials and energy and, hence, costs are reduced. The novel solar cells reach about the same efficiency as conventional organic solar cells. Last year, the project received Gips-Schüle Foundation’s 50,000 Euro research award.

Flexible and without solvents hazardous to health: The solar cells developed by KIT (Photo: Alexander Colsmann, KIT)

Light Technology: Printing Process Makes 3D Objects Glow

Conventional electroluminescent (EL) foils can be applied easily to flat surfaces, but they can be bent to a certain degree only. The new process developed by KIT in cooperation with the company of Franz Binder GmbH & Co Elektrische Bauelemente KG now for the first time allows for direct printing of electroluminescent layers onto three-dimensional components and curved surfaces. “In conventional EL carrier foils, the luminescent material is located between two plastic layers. By means of our new printing process, the luminescent material is printed directly onto the object without any intermediate carrier,” Dr. Rainer Kling of the Light Technology Institute of KIT says. In this way, curved surfaces and even spheres of various materials, such as paper or plastic, can be made luminescent. Such EL components might be used to enhance safety in buildings in case of power failures. Other potential applications are displays and watches or the creative design of rooms. The development project was funded by the Deutsche Bundesstiftung Umwelt (German Foundation for the Environment).

Flexible and curved surfaces can be made luminescent, no matter whether they are made of paper or plastics. (Photo: S. Walter, Binder Gruppe)

Lightweight Construction: Automated Process Chain for Preforming Textile Materials

Reduction of CO2 emission and energy consumption of vehicles is a central objective for the energy transition and climate protection and, hence, a driver of lightweight construction. The resin transfer molding process is of high potential for the series production of lightweight, fiber-reinforced plastics. In the course of this process, a textile preform is impregnated with a plastic and hardened in a mold. The wbk Institute of Production Science of KIT will present a demonstrator of process automation for textile preforming. Flat textile materials are transformed into a complex, three-dimensional fiber structure. An intelligent, resource-efficient gripping system is developed as a key technology for handling.

Intelligent gripping system for handling semi-finished textile parts. (Photo: wbk, KIT)

High-performance Polymers from the 3D Printer: Indmatec GmbH

Heat and cold, shocks and friction: The materials used in vehicles and manufacturing machines have to survive high loads. Indmatec GmbH, a spinoff of KIT, has made the high-performance polymer of polyetheretherketone, PEEK, fit for 3D printing by fused filament fabrication. “Our specially developed printer produces a layered structure of high temperature and mechanical stability,” Managing Director Tony Tran-Mai says. The innovative material cannot only be used in automotive and mechanical engineering, but also in electrical engineering and semiconductor industry as well as in medicine, e.g. for the fabrication of implants or prostheses. The spinoff of KIT was chosen to be the best startup during this year’s Venture Capital Pitch in Baden-Württemberg.

Implants from the 3D printer: The high-performance polymers made by Indmatec GmbH are also interesting for use in medicine. (Photo: Indmatec GmbH)

Network for Nanotechnology: NanoMat

Nanotechnology materials are in the focus of the supraregional NanoMat competence network that has its office at KIT. Among the NanoMat members are partners of industry and science. Their goal is to support application-oriented research in joint projects. NanoMat fosters knowledge and technology transfer to bridge the gap between research and development.

Technology Offerings

RESEARCH TO BUSINESS, the technology market of KIT, will present 90 technology offerings. Among them are innovations made by KIT, which can be used as a basis for marketable products and processes.

KIT Participation in Other Stands

- Hall 2, A01 – BIOKON platform:Lightweight construction modeled on nature

- Hall 2, C40 – VDI/TU9: Video portrait of KIT

- Hall 2, C50 – Joint stand BIOPRO Baden-Württemberg presenting the bioliq project: Fuels from biomass

- Hall 3, B35 – Joint stand of the Helmholtz Association presenting KIT startups

- Hall 6, L42 – MIMAN-T, Micromanufacturing Training Systems for SMEs

Further information can be found in the digital press kit: http://www.pkm.kit.edu/english/hannovermesse2016

Being “The University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.