Ceramic vases and battery electrodes serve different purposes, but have an important production step in common: Only at very high temperatures are they given their excellent properties. For this reason, the chemist Andrew P. Vogt of KIT uses the kilns of the Majolika Ceramics Manufactory in Karlsruhe for his materials research project. He applies tailored plastic molecules to develop prototypes of nanostructured carbon materials for bat-tery electrodes or chemical catalysts.

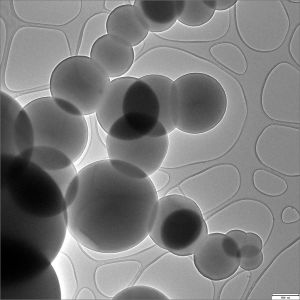

“For my research, it is sheer luck that the kilns of the Majolika are located just around the corner of the campus,” Andrew Vogt brims with enthusiasm. Already during his Ph. D. phase he developed processes to generate small structures in materials. Nanostructured materials may be applied as filters to clean contaminated water or as chemical catalysts. They might also be suited for batteries or electronics. Carbon rich materials can be nanostructured as well, where even thin samples do not tear and are easy to modify chemically.

To produce nanostructured materials, Vogt uses long-chain “polymer” molecules, i.e. plastics. With the help of additives, various polymer types with precisely adjusted properties can be produced. “Then, we have to carefully decompose the molecules to obtain carbon rich structures in vacuum tanks with extreme heat,” Vogt states explaining the process of the so-called “pyrolysis”. The kilns at Majolika have turned out to be a suitable tool for this purpose.

To successfully decompose the polymers and generate carbon rich structures, the temperature has to be controlled precisely at a particular rate of time. The samples are heated up to more than 800°C. “The Majolika operates high-performance kilns, whose temperature does not fluctuate,” Vogt says. The kilns are equipped with very thick walls, because a constant temperature also is of great importance when baking and glazing large ceramic vases and tiles. Temperature fluctuations may cause the color to deviate or cracks to develop.

Vogt, who conducts research at the KIT Chair for Preparative Macromolecular Chemistry of Christopher Barner-Kowollik under a grant of the Alexander von Humboldt Foundation, is presently examining the novel carbon nanostructures for applicability. Stable, nanoporous filters, for instance, might be used for cleaning water or oil. Chemical catalysts might be applied for the production of chemicals or battery electrodes with enhanced properties. “We are only at the beginning, but conversations with colleagues at KIT have already revealed exciting perspectives,” Barner-Kowollik and Vogt exclaim - summing up the status of research at the moment.