Lithium-ion batteries are important for the proclaimed “Energiewende”, the transformation of the energy system. They are needed for the storage of electricity from fluctuating renewable sources or for the operation of electric vehicles. However, high costs still represent a major challenge, which has to be faced for the technology to be competitive. After three years of research, a team headed by Professor Wilhelm Schabel and Dr. Philip Scharfer of the Thin Film Technology (TFT) group of the KIT Institute of Thermal Process Engineering has succeeded in increasing the speed of intermittent production of the electrode foils representing the actual energy storage systems to 100 meters per minute. So far, 25 to 35 meters per minute have been the industrial state of the art. Within the project “Competence E”, the scientists developed a revolutionary coating technology, by means of which it is not only possible to produce continuous coatings, but also patterns featuring high precision. A patent has been filed for this invention.

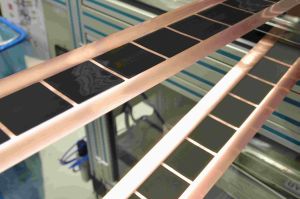

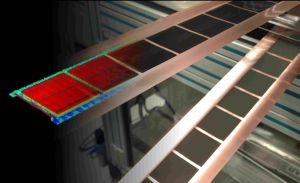

When producing an electrode foil, a slurry containing the active material, carbon black, binder, solvent, and additives is applied onto a substrate foil made of copper (for the anode) or aluminum (for the cathode). The coating is often processed continuously, however intermittent coatings are associated with a superior processability for subsequent process steps. “In case of intermittent coating, defined start and stop edges are required no matter the coating speed,” Schabel explains. “In our process this is achieved by a membrane that quickly moves back and forth in a controlled manner in the coating head, i.e. in the slot die.” Other movable parts are not required. This results in high frequencies of up to 1000 electrode patterns per minute and highly precise coating. By optimizing membrane parameters, the process can be adapted in-situ to the properties of the coating medium. In their “Roadmap for Battery Production”, the German Engineering Association (VDMA) defined the goal of reaching a coating speed of 100 meters per minute until the year of 2030. This goal has already been scored by KIT scientists today.

With this new technology, electrode production can be increased by a factor of 3 at about the same investment costs. As a result, production costs of lithium-ion batteries can be reduced drastically. With a similar process, the KIT scientists have already produced electrodes for electric vehicles in pilot scale successfully. Dr. Andreas Gutsch, head of “Competence E” at KIT, points out: “The new coating technology in combination with the helix technology developed and patented by KIT for the production of spirally wound lithium-ion batteries, offers the potential of reaching cost leadership.”

The Karlsruhe Institute of Technology (KIT) is one of Europe’s leading energy research establishments. Research, education, and innovation at KIT foster the energy turnaround and reorganization of the energy system in Germany. For this, KIT links excellent competences in engineering and science with know-how in economics, the humanities, and social science as well as law. The activities of the KIT Energy Center are organized in seven topics: Energy conversion, renewable energies, energy storage and distribution, efficient energy use, fusion technology, nuclear power and safety, and energy systems analysis. Clear priorities lie in the areas of energy efficiency and renewable energies, energy storage technologies and grids, electric mobility, and enhanced international cooperation in research.

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.