Infections of implants are much dreaded problems that may occur after medical interventions. About 2 – 6% of all patients are affected. Scientists of the KIT Institute of Functional Interfaces (IFG) have now succeeded in developing a biocompatible coating, that at controlled laboratory conditions and in an animal model, was able to prevent a biofilm formation for one week on the implant material titanium. It prevents the bacteria from settling on the implants and initiating serious infections due to the formation of biofilms. In animal experiments, the protective coating proved to be highly efficient and biocompatible at the same time. The results were published in the prestigious journal “Biomaterials”.

In cooperation with colleagues from the University of British Columbia, IFG scientists first screened compounds for a potential protective effect against an infection on a surface. They studied antimicrobial peptides (AMPs), small proteins consisting of a short chain of aminoacids. These AMPs are of high interest for fighting infections, because they can kill both gram-negative and gram-positive bacteria as well as fungi, viruses or parasites and, hence, have a very wide effect.

In a next step, peptides with an antibiotic effect were fixed on implant surfaces by polymers. The construct that resembles a bottle brush has several advantages: “Due to the polymer pattern and its particular shape, we could increase the concentration of peptides. Fixation prevents the antimicrobial peptides from diffusing,” explains the head of the project, Dr. Kai Hilpert.

Methods exist to impregnate implants with antimicrobial substances to prevent local infection. So far, this method has been hardly successful, if not counteractive. “The diffusion of antibiotics results in a concentration gradient that promotes development of resistance of the bacteria,” emphasizes Hilpert. In addition, there is the risk of so-called adaptive resistance. “Due to the gradient, the bacteria can adapt very early to the effective substance and activate defense strategies. As a result, they survive a higher antibiotic concentration,” says Hilpert.

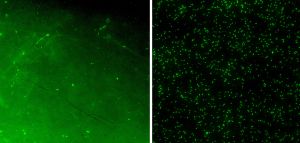

The infections on implants are caused by biofilms. They form when bacteria attach to the implant. “The bacteria release certain substances that form a framework in which bacteria can grow three-dimensionally and specialize within this system,” says Hilpert. Biofilms are far more resistant to antibiotics. In order to kill bacteria in biofilms, the antibiotics concentrations have to be increased by a factor of up to thousand. ”Surprisingly, the AMPs in our construct prevent biofilm formation, at least for a week. Long-term experiments are necessary to determine the application on real implants. ” explains Hilpert. When the coated implant pieces were placed in a nutrient solution for one week with a very high concentration of bacteria, the scientists detected hardly any bacterial growth contrary to uncoated implants. Efficiency was also confirmed by an animal experiment. Experiments using cell cultures and rats demonstrated that the protective coating is biocompatible, i.e. harmless to body cells. So far, coatings of titanium surfaces have been studied, as this material is used for very many implants. “The same principle may also be applied to other surfaces, for example to plastic catheters,” says Hilpert.

“The results obtained by Dr. Hilpert and his colleagues open up a new and rather attractive option for coating implants. At the moment, the underlying effect mechanisms are being investigated extensively by IFG and technical basics are developed for rapid implementation.” IFG director Professor Dr. Christof Wöll describes future work.

Link to the study (March 06, 2011):

Biomaterials

Volume 32, Issue 16, June 2011, Pages 3899-3909

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 10,000 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,800 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.